Stand out with a band!

Film or paper?

Increase sustainability

Save 80% material

Rent a Bandall

Visit our virtual booth

Banding for a sustainable world

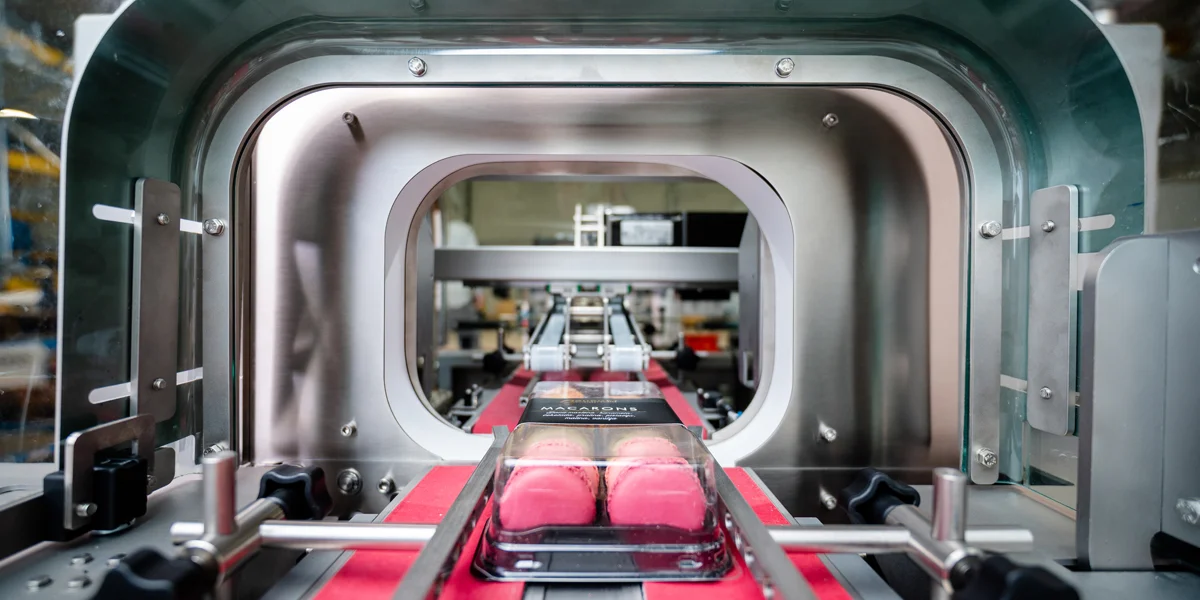

Sustainable bundling, labelling and/or sealing, with just a strip of paper or film. It is possible with Bandall banding machines. The word sustainable takes on a real meaning. You can easily save 80% of packaging material.

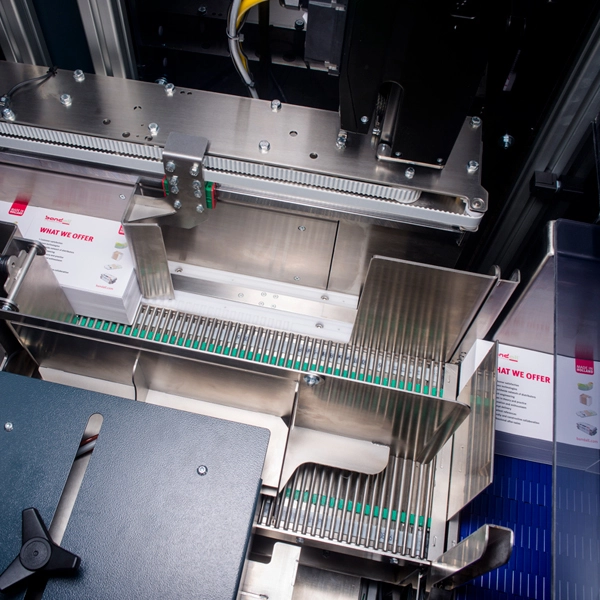

What is banding?

Banding is the process where one or multiple products are wrapped with a thin band of paper or film. It's an extremely efficient technique for bundling, labelling or sealing products.

Rent a Bandall

In addition to purchasing options, we also offer rental and lease options in many countries. Temporary sales promotions or promotional packaging sometimes require temporary banding solutions.

Videos

Print & band

Our colleagues Nick and Stijn show the basics of the Print & Band concept.

Multi-Width

The Multi-Width option makes it possible to use different band widths on one machine.

Replacing shrink film

The new Bandall TRLS is extremely modular and flexible in use.

Current topics

Calendar

Seafood

Barcelona, Spain

Stand: 3KK201

Bandall BV

Hispack

Barcelona, Spain

Stand: TBA

Bandall Iberica

Drupa

Düsseldorf, Germany

Hall 6 Stand: B03

Bandall BV

PLMA

Amsterdam, The Netherlands

Stand: TBA

Bandall BV

Mexipan

Citibanamex, Mexico

Stand: 580

AERSA

Fachpack

Nuremberg, Germany

Stand: TBA

Bandall BV

Sial

Paris, France

Stand: TBA

Bandall BV

Syskevasia 2024

Hall: 3 Stand: D12-14 / E11-13

Pascal Packaging

Pack Expo

Chicago, United States of America

Stand: TBA

Bandall Inc

All4Pack

Paris, France

Stand: TBA

GETRA s.a.s.