Bandall's banding machines

The standard in banding

As the leading name in banding solutions, we deliver top-quality, reliable, and custom-tailored banding machines. Our offerings range from Stand Alone units to fully automated systems designed for high-demand packaging environments.

Our range of banding machines

Whatever your packaging challenge may be, Bandall has the solution. From Stand Alone machines that you can start using right away to fully Automated Production Lines that match your needs and production speed.

Stand Alone

20 units per minute

Automatic

Modular

Tailor-made

Industry leaders choose Bandall

Bandall machines offer unmatched reliability, flexibility, and ease of use—making them the top choice for industry leaders worldwide.

- User-friendly design

- Longest machine life

- Worldwide professional support and service

- The widest possible bandwidth

- Global network of material suppliers

- Highest production speeds

- Easy change to different band widths

- Easily print variable product information

- Easy integration & customization

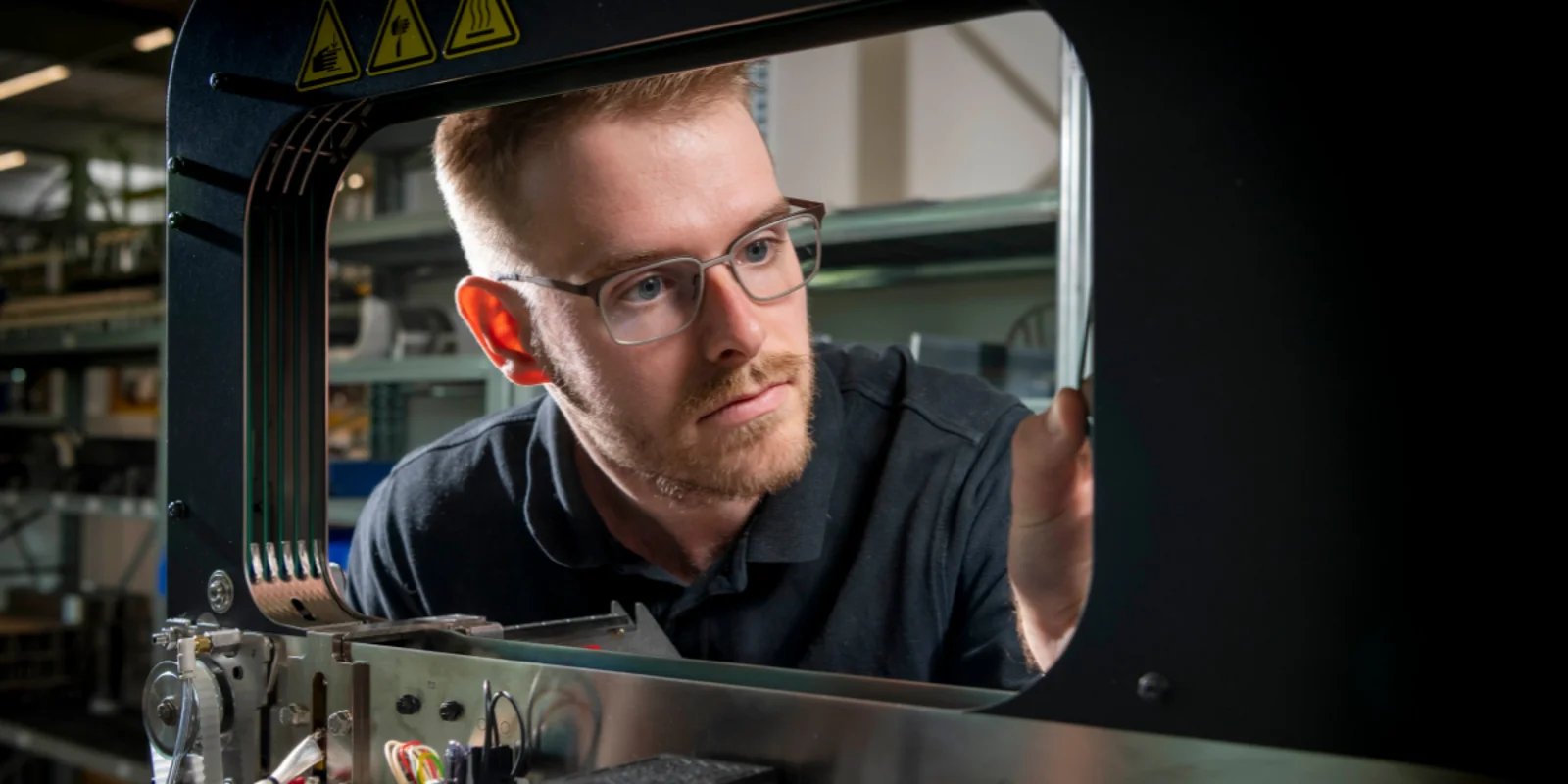

User-friendly design

Bandall machines are designed with user-friendliness in mind, making them easier to operate and maintain. Changing a band or adjusting to a different product type is very simple. Simply add or remove components to or from the arch, change the material, and you are ready to go! Additionally, all our machines feature a user-friendly touchscreen and operate using pictograms, making them easy to use without the need for language.

Longest machine life

It’s no surprise that our machines continue to operate seamlessly after 25 million cycles in a fast-paced production environment. This is due to our use of high-quality materials and our unique band feed-through technology, which is unmatched in the market. This system completely eliminates friction in the arch and reduces the number of wear parts, resulting in less maintenance, fewer repairs, and more consistent performance - all contributing to a longer overall lifespan for the machine.

Minimal downtime

Downtime in an automated production environment can be extremely expensive. It stops high-volume output, disrupting supply chains and resulting in missed deliveries.Our machines are technologically superior, which means you will experience significantly fewer disruptions compared to cheap counterfeits. Don’t be short sighted when it comes to your investment.Additionally, we offer maintenance contracts to ensure your your operations keep running smoothly. Finally, we keep a wide range of parts in stock, ready for express shipping if needed.

Strong seal on any material OR Flawlessly controlled welding process

Our advanced system actively measures the sealing head temperature and power output, ensuring a flawlessly controlled welding process. When you engage the machine, it intelligently increases power, and when idle, it reduces power to optimize efficiency. Unlike budget banding machines with fixed-output heating elements that deliver a constant power, our machine adapts to your needs—delivering power only when necessary, saving energy and enhancing performance.

You can also easily set the welding and cooldown times. For example, 50-micron material requires a different welding time than thick paper. All of this can be adjusted, with easy-to-understand icons guiding you through each setting.

Highest production speeds

If you’re looking to maximize efficiency with unbeatable production speeds, our machines are designed for you. Perfect for handling extremely high volumes, our advanced multi-head models lead the industry, processing up to 240 products per minute with precision and reliability. These machines are engineered to keep up with the most demanding production lines

Easy integration into existing lines

Many customization options

Process the thinnest as well as the widest bands

Our machines leverage unique technology that allows them to process materials as thin as 35 micron, the lowest in the market. This saves packaging material, reduces transportation and storage costs and promotes sustainability. In a high production environment, it can lead to substantial savings of thousands of kilograms of material each year. Furthermore, our machines are capable of processing band widths up to 150mm, the largest in the market. In addition, our machines have the narrowest arches relative to the band widths, convenient when space is limited in your production facility.

Easily change to different band widths

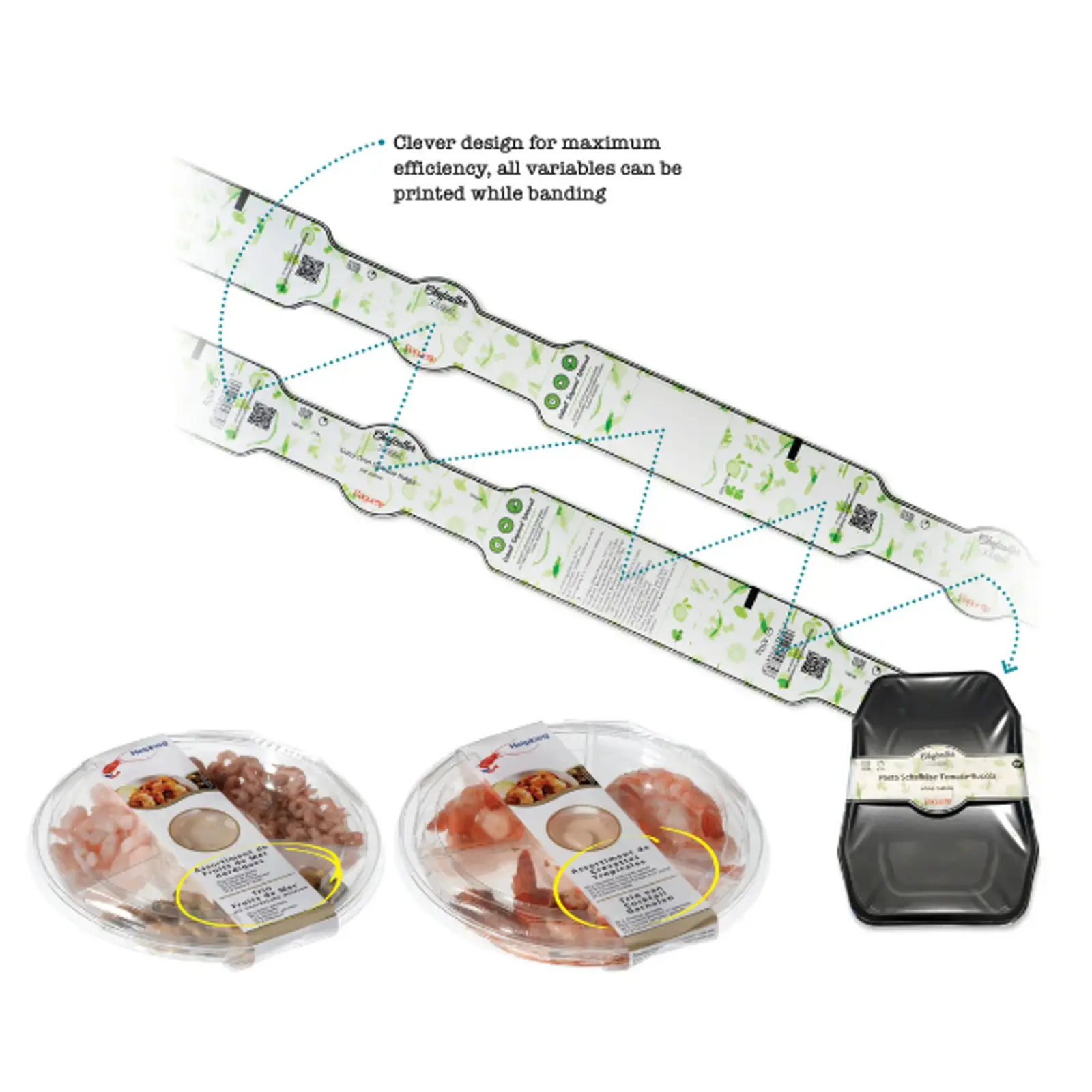

Effortlessly add variable data such as barcodes during packaging

global network of material suppliers

We have a global network of material suppliers. This offers numerous benefits, including diverse sourcing options, cost efficiency, and access to innovative, high-quality materials. When you buy the machine, you gain access to the entire packaging concept. If you work with one of our partners, we support you in the design process to ensure it goes smoothly. However, we do not require you in any way to purchase materials from any of our partners.

Why band with Bandall?

Worldwide professional support and service

When you purchase one of our machines, you gain access to exceptional professional support and service. This support ensures that you receive expert guidance during installation and operation, allowing you to maximize the machine's performance and efficiency right from the start.

- Installation & training

- Maintenance & support

- Worldwide support desk

- Fast repair service

- Material service

- Advice on scaling, expanding, and changing

By choosing Bandall, you are investing in reliable, innovative and efficient packaging solutions that are sustainable and future-proof.

Flexible financing

At Bandall, we understand that investing in a machine is a significant decision, which is why we offer flexible financing options.

- Purchase - Purchase allows you to invest in a sustainable and efficient packaging solution that will enhance your operations for years to come.

- Renting - Renting gives you the flexibility to use the machine for a set period. It includes the possibility of purchasing the machine at the end of the rental term, ideal for evaluating this method of packaging without long-term commitment.

- Trial period - Test the machine for a week before deciding to purchase or rent.

See banding in action

Textile factory Zwartz

Fish monger Klooster

Novatrade