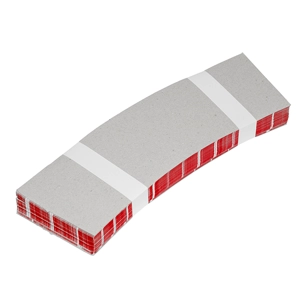

Bundling paper products

Reduce costs by banding

Are high packaging costs squeezing your margins? What if you could cut down on energy, material, and labor costs when bundling paper products?

Bands make it possible, it is the smart, sustainable alternative to shrink wrap, straps and boxes.

Effortless application

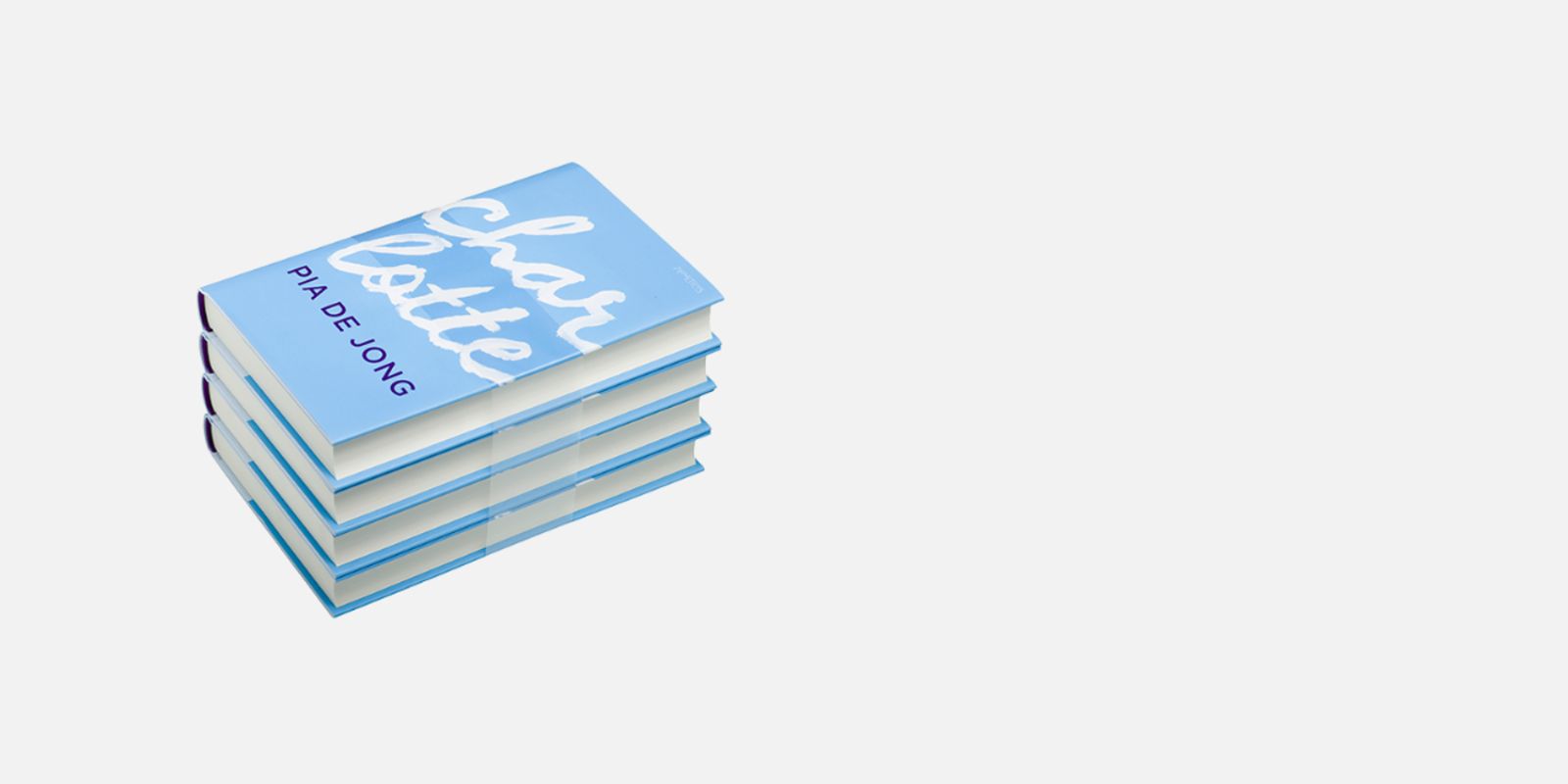

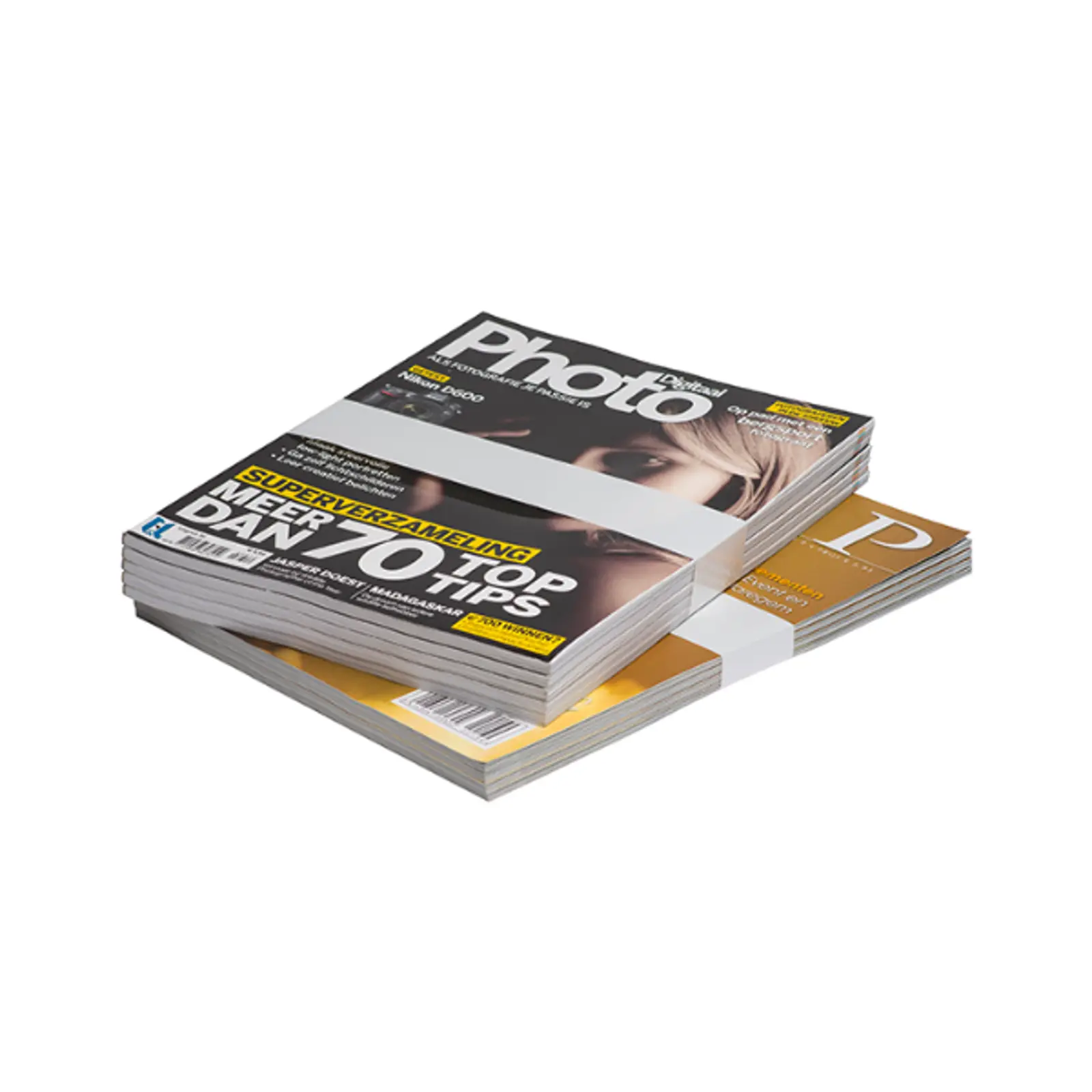

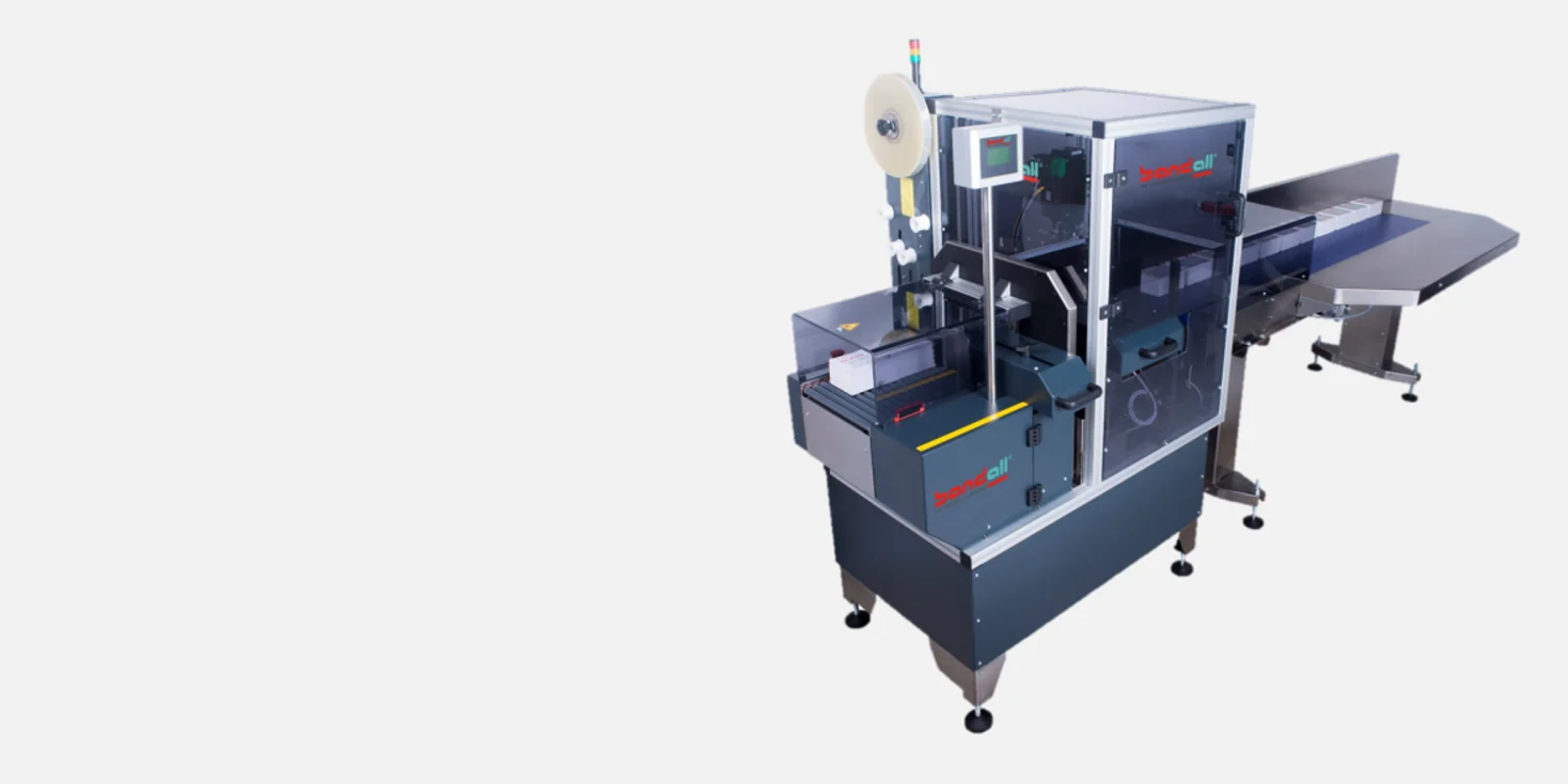

With just one secure band, your paper products, such as books, magazines, and brochures, are neatly bundled into a stable stack. Our banding machines, available in both fully automated and Stand Alone models, ensure effortless operation and reliable results without the need for additional handling.

Our banding machinesBanding saves cost

Banding helps printing companies cut costs when bundling by:

- Using less material

- Reducing labor

- Cutting energy use

- Boosting efficiency

- Lowering shipping costs

The most sustainable solution

Banding is the most sustainable bundling method because it uses less material, reduces waste, and requires no heat, unlike shrink film, making it energy-efficient. Additionally, bands are usually made from recyclable materials, further reducing environmental impact.

Our banding machines

Since 1990, we have been developing sustainable and efficient packaging solutions. Our banding machines help brands and packagers worldwide streamline operations, enhance branding, and reduce packaging waste.

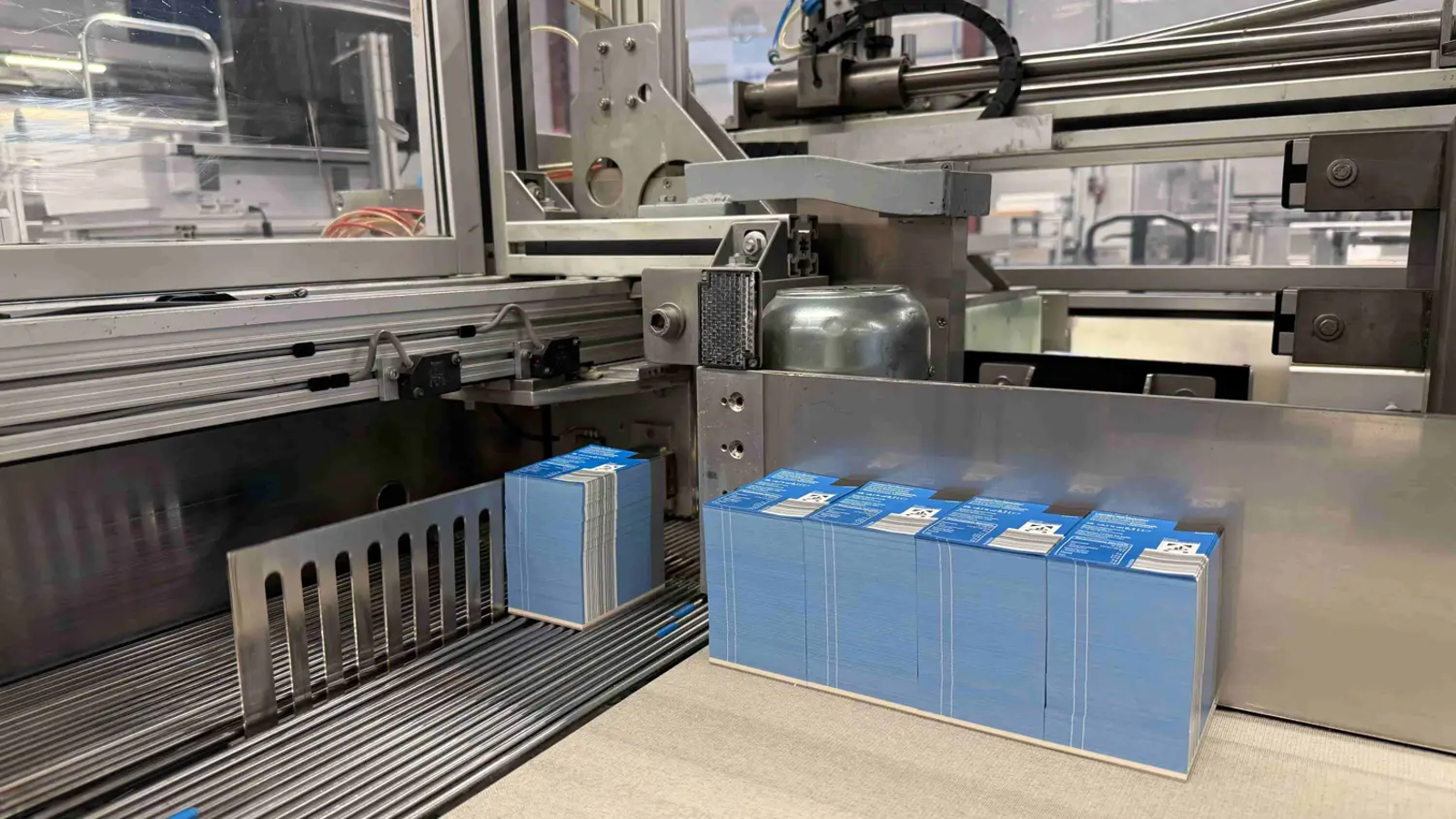

Royal Sens saves by smart bundling

As one of the biggest label producers in Europe, Royal Sens has already made the switch from manual packing to automated banding, with great results. By integrating Bandall systems, they’ve significantly improved efficiency, reduced packaging waste, and future-proofed their operations.

Paper products bundled by us

Printed matter

Labels