Automated packaging solutions

Maximize your efficiency

Do you struggle with slow packaging speeds? Are you ready to scale and take the next step with automation?

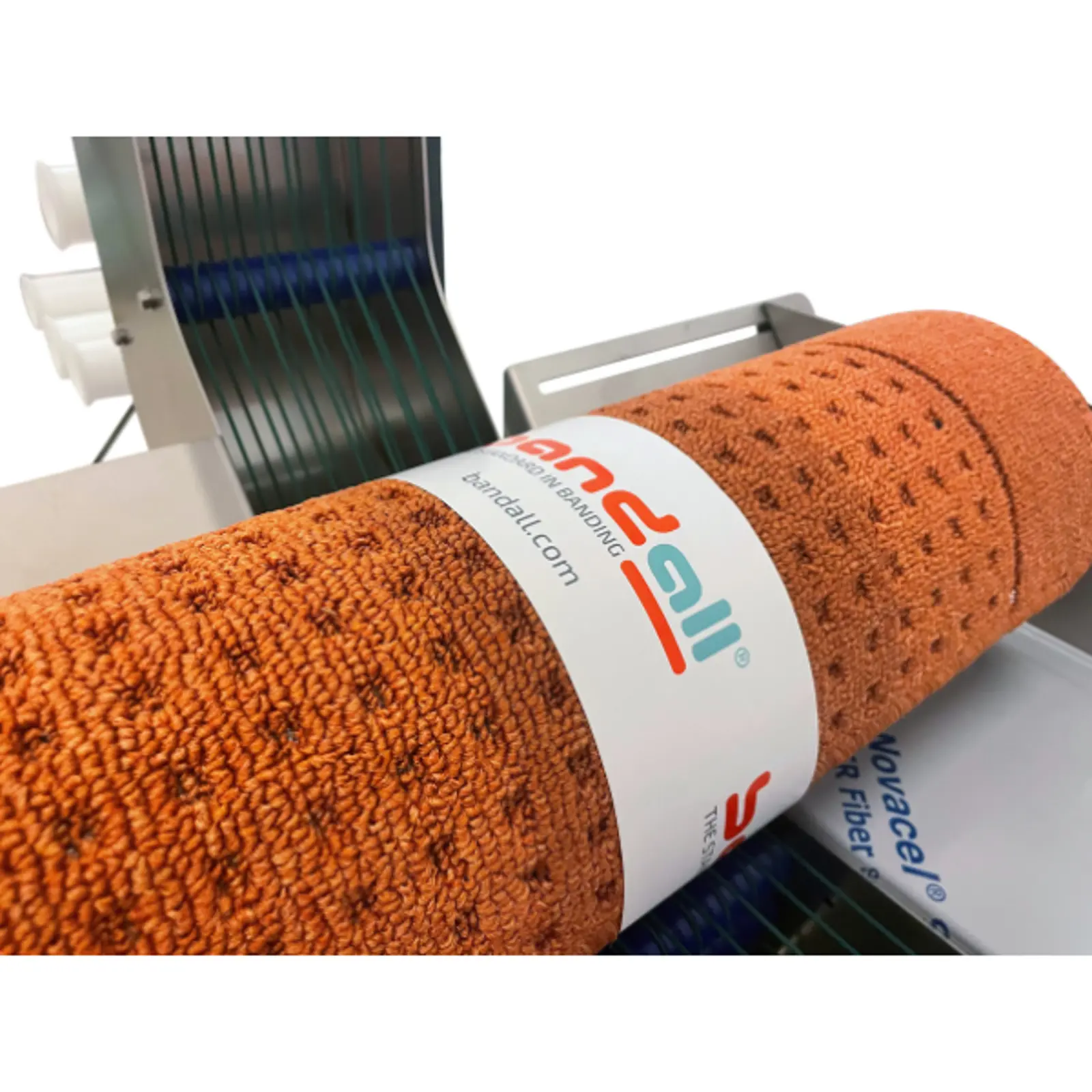

Automated banding offers a faster, more efficient way to package your products, all while using less material.

Are you ready to start automating?

Achieve more with automation

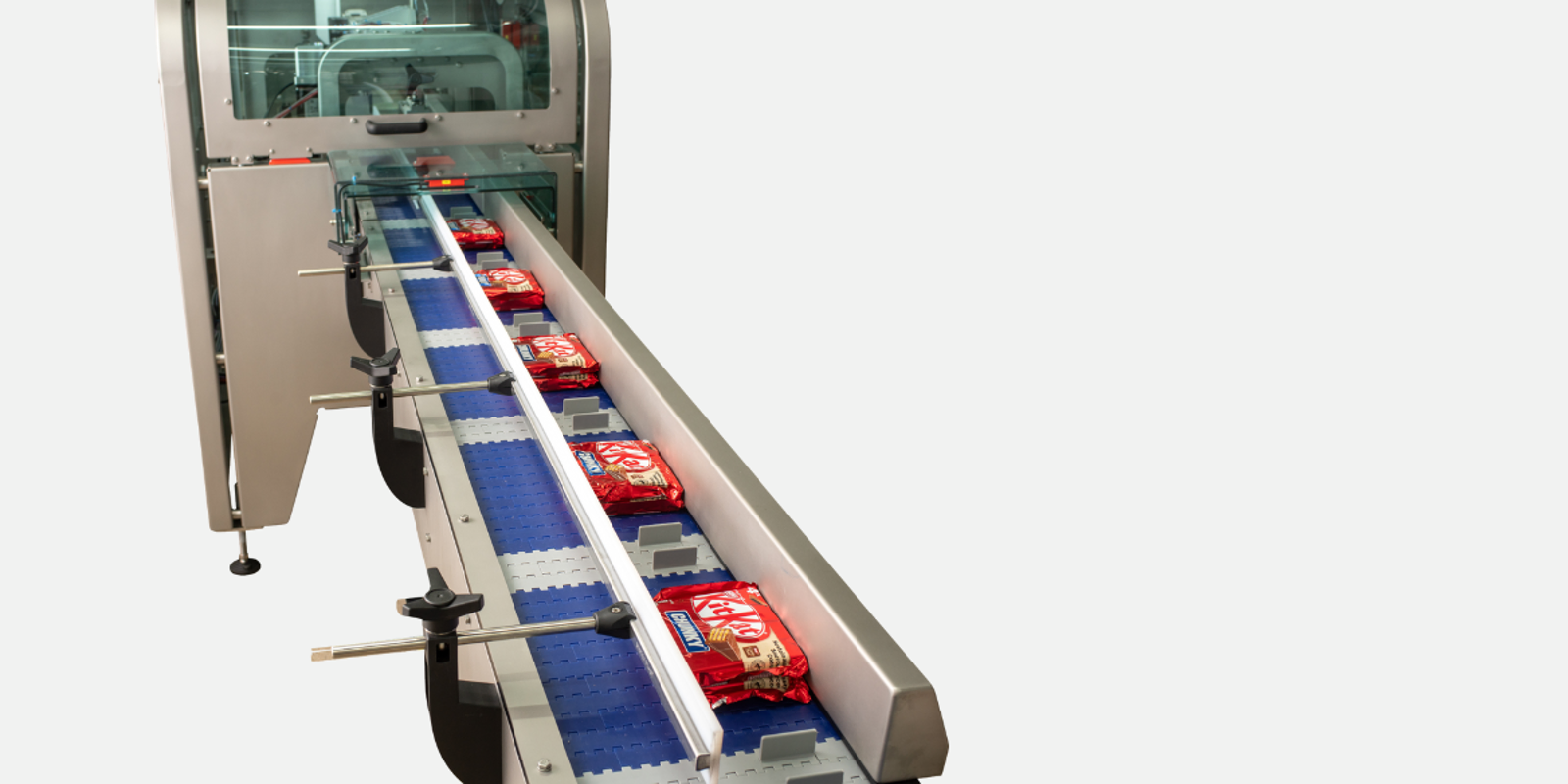

By eliminating manual packaging processes, you can effortlessly streamline your operations and boost efficiency. With automated packaging, you can handle higher product volumes in less time while staying ahead of sustainability goals.

Work smarter, eliminate errors

With automation, your packaging becomes more accurate, flexible, and refined. It transforms your workflow by boosting speed and minimizing errors:

Versatility across sizes

Advanced systems adjust seamlessly to different product dimensions.

Real-time quality checks

Automated systems detect and correct errors instantly.

Perfect band tension

Always ensuring precise tension and alignment for every product.

Uninterrupted performance

Automated packaging empowers your operation to run 24/7 and break free from the 9-to-5 workday schedule. With minimal manual intervention, automation keeps your production line moving nonstop. It delivers reliable results whenever your packaging operation needs to run.

Error-free packaging

By replacing manual tasks with programmed systems, automated packaging eliminates common errors, such as misaligned packaging or inconsistent application. Additionally, advanced sensors and monitoring tools detect irregularities in real time, allowing issues to be addressed efficiently.

Solve workforce gaps

Automated packaging offers a smart and efficient solution to labor shortages. With automated packaging you can hand over the task of keeping production running smoothly and obtaining consistent results with less labor.

Why automation matters

- Streamlined packaging process

- Handle large volumes with ease

- Replace manual processes

- Smooth product transport from start to finish

- Easily integrated into (existing) packaging lines

- The band is sealed at optimal tension

- Less material, energy, and labor required

- Less packaging waste

Success stories from our customers

Textile factory Zwartz

Fish monger Klooster

Lisner

AGF-Holland

Our banding machines

Stand Alone

Automatic

Modular