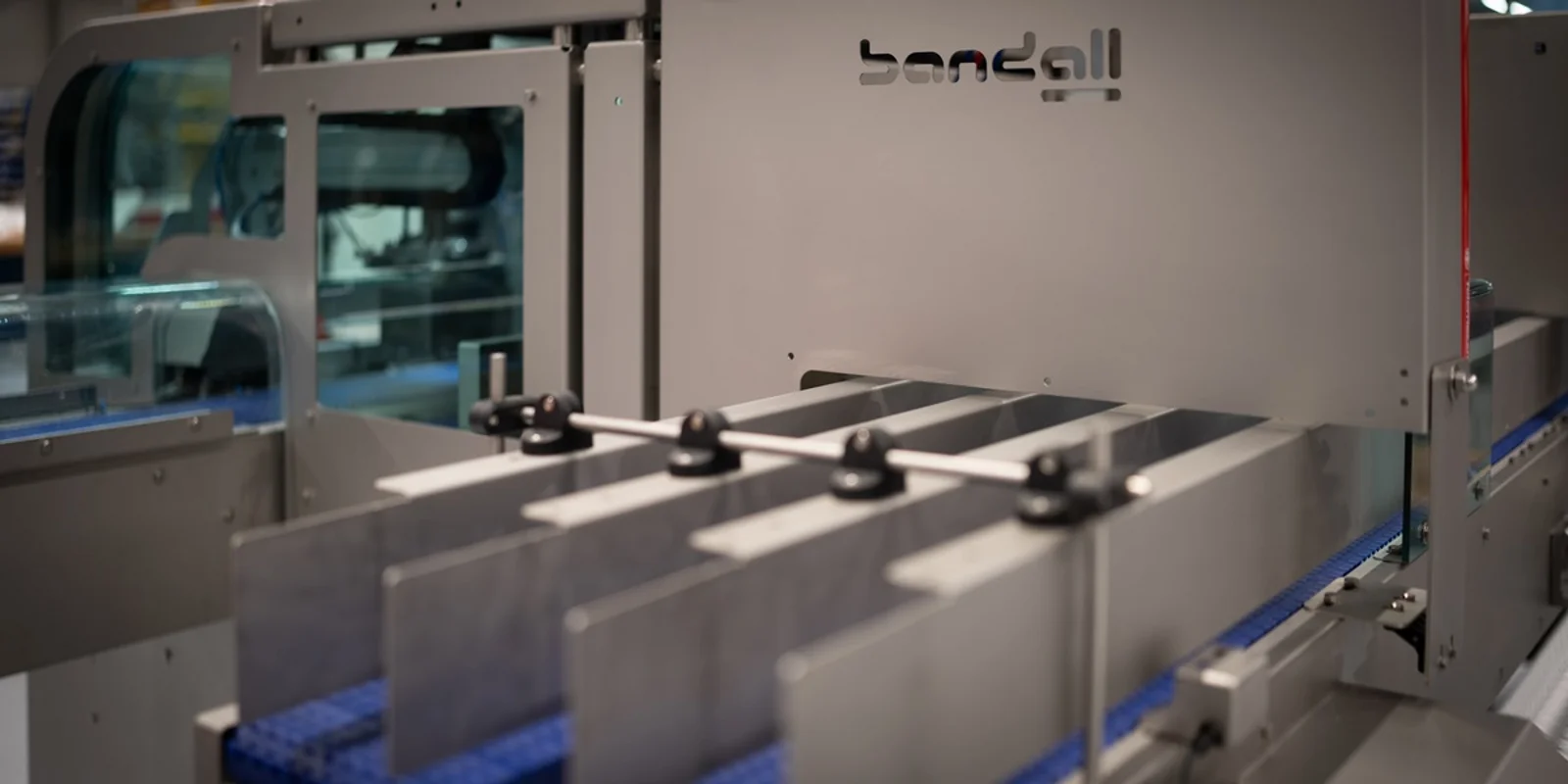

Multi-head machines

For ultimate performance

Maximize efficiency with our cutting-edge multi-head machines! Designed for high-performance, they are capable of packaging multiple products at once. This significantly reduces cycle times and speeds up your production throughput. Get more done in less time!

Built for high-speed performance

Built for high-speed performance, our multi-head machine bands up to 120 products per minute, outpacing single-head automatic machines. The perfect solution for large-scale packaging operations!

Benefits of using a multi-head

- Highest production output - With six heads, it is possible to band up to 120 products per minute.

- Maintenance without downtime - You can perform maintenance on one head while continuing production with the others. It's also possible to remove a head for servicing and replace it with a spare to keep operations running smoothly.

Potential configurations

Enhance the power of our multi-head machines with these high-performance configurations, each designed to boost functionality and provide even greater flexibility:

- Automatic positioning system - Ensures various elements of the design will always be in the correct place in relation to your product.

- Print & Band - Add a printer to include details like barcodes, product information, or logos directly onto the band.

- Integrated stacking machine - This allows you to efficiently and quickly stack your products before packaging

- Adjustable component sizes - Tailor the machine to fit your specific needs with customizable arch sizes and conveyor belt widths.

- Stainless steel - For environments that require extra durability and hygiene, choose stainless steel.

- Various infeed conveyors - Select from a range of infeed conveyors, including label bander, low-friction food-grade, or roller conveyors.

Why band with Bandall?

Klooster succesfully switched to bands

Fish monger Klooster couldn't be more pleased with their decision to switch to bands. Reflecting on the transition, Commercial Director Jac Tijsen expresses his satisfaction: 'Since making the switch, we’ve thrived with a faster, more cost-effective packaging solution.'

Flexible financing

At Bandall, we understand that investing in a machine is a significant decision, which is why we offer flexible financing options.

- Purchase - Purchase allows you to invest in a sustainable and efficient packaging solution that will enhance your operations for years to come.

- Renting - Renting gives you the flexibility to use the machine for a set period. It includes the possibility of purchasing the machine at the end of the rental term, ideal for evaluating this method of packaging without long-term commitment.

- Trial period - Test the machine for a week before deciding to purchase or rent.

Contact

Discover your perfect packaging solution

Bandall's range of machines

Stand Alone

Automatic