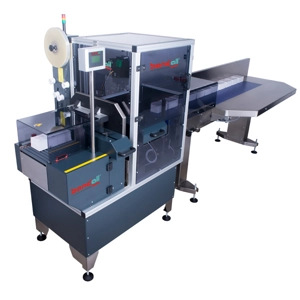

Bandall TXL Series

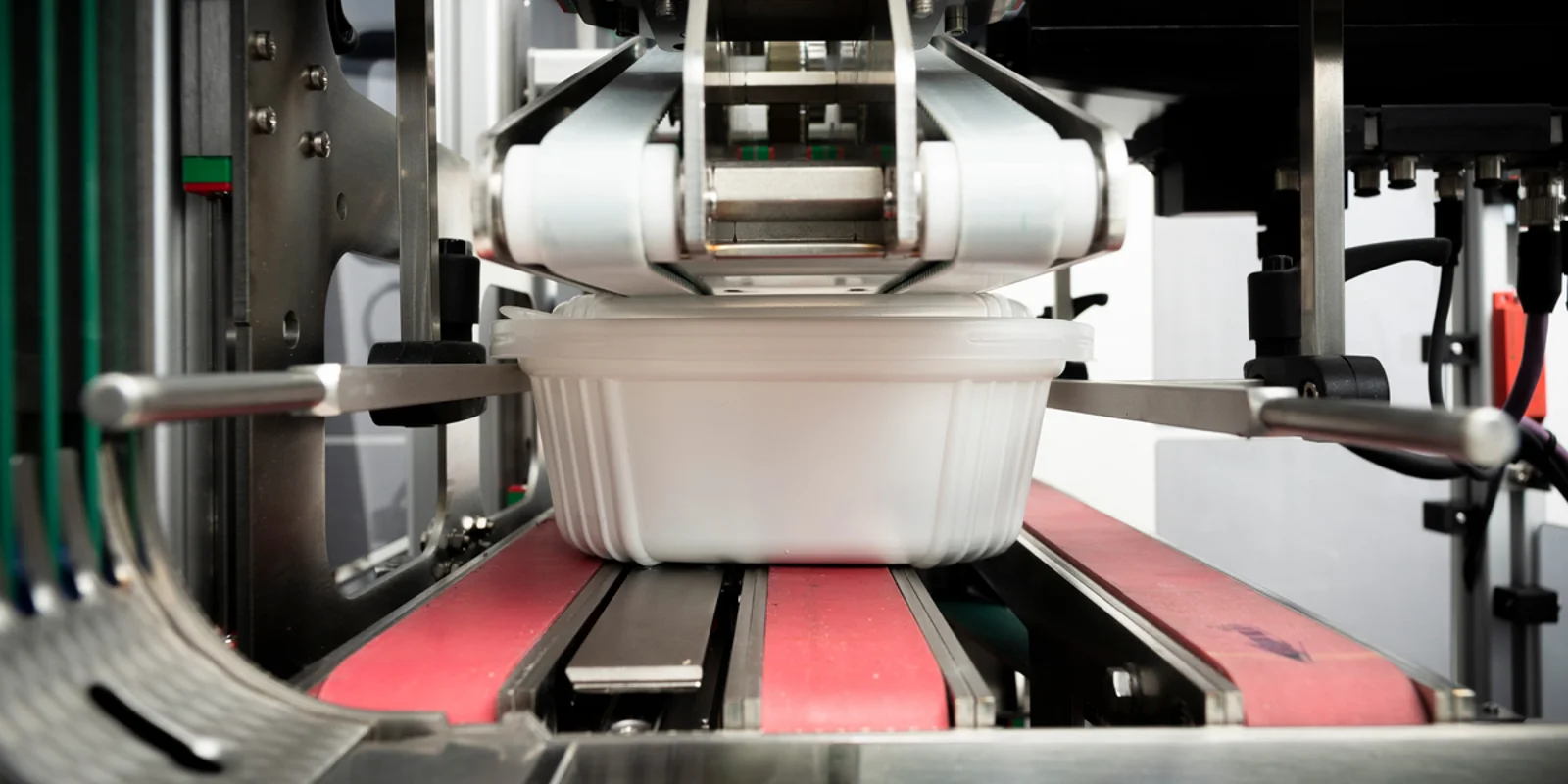

The Bandall TXL Series is engineered for maximum grip and speed. With transport belts that firmly grip products from both the top and bottom, the TXL ensures secure and precise linear movement into the arch. The bottom and top grip is particularly beneficial for products with lids or loose tops, preventing them from shifting or coming off during packaging. The result? A fast, accurate, and secure linear packaging setup.

Key features of the TXL

- Perfect band placement - The top and upper transport ensures the band is always placed exactly where it needs to be.

- Smooth workflow - The conveyor system guides products smoothly through the TXL's arch without interruptions.

- Smart alerts - The machine has indicator lights that tell you when the machine is in run-mode, or when the material is about to run out.

- Reel holder - The design of the reel holder makes it simple to place and remove the material.

- Multi-banding - The TXL is able to apply multiple bands to a product.

- Adjustable height - Effortlessly integrate the machine into your existing setup ensuring a perfect fit

- Unique arch vacuum system - This system ensures the material moves smoothly through the arch and stays securely in place.

Double transport system

The double transport belt system makes the Bandall TXL suitable for the very fast and accurate transportation and packaging of containers, boxes, and trays. In the food industry, the machines are often used for biscuits, frozen products, salads, and ready-made meals. Products suitable for the Bandall TXL have a flat top and bottom that allows them to be carried by the two conveyor belts.

Potential configurations

Enhance the power of the TXL with these high-performance add-ons, each designed to boost functionality and provide even greater flexibility:

- Band positioning technology - This ensures that every element of your design is perfectly aligned and positioned on your product.

- Printer - Add a printer to include details like barcodes, product information, or logos directly onto the band.

- Adjustable component sizes - Tailor the TXL to fit your specific needs with customizable arch sizes and conveyor belt widths.

- Stainless steel design - For environments that require extra durability and hygiene, choose stainless steel.

- Various infeed conveyors - Select from a range of infeed conveyors, including low-friction food-grade or roller conveyor options.

Why band with Bandall?

How WreppieS transformed its shelf appeal with eye-catching bands

WreppieS has become a standout sensation on the shelves, captivating consumers with its vibrant, irresistible packaging. Vice President Erwin Trapman credits Bandall with being a key player in their success, helping them evolve from basic white labels to attention-grabbing bands that truly shine.

Flexible financing

At Bandall, we understand that investing in a machine is a significant decision, which is why we offer flexible financing options.

- Purchase - Purchase allows you to invest in a sustainable and efficient packaging solution that will enhance your operations for years to come.

- Renting - Renting gives you the flexibility to use the machine for a set period. It includes the possibility of purchasing the machine at the end of the rental term, ideal for evaluating this method of packaging without long-term commitment.

- Trial period - Test the machine for a week before deciding to purchase or rent.

Read more on the TXL by downloading our brochure below!

Our other automatic models

TRL Series

TRC Series