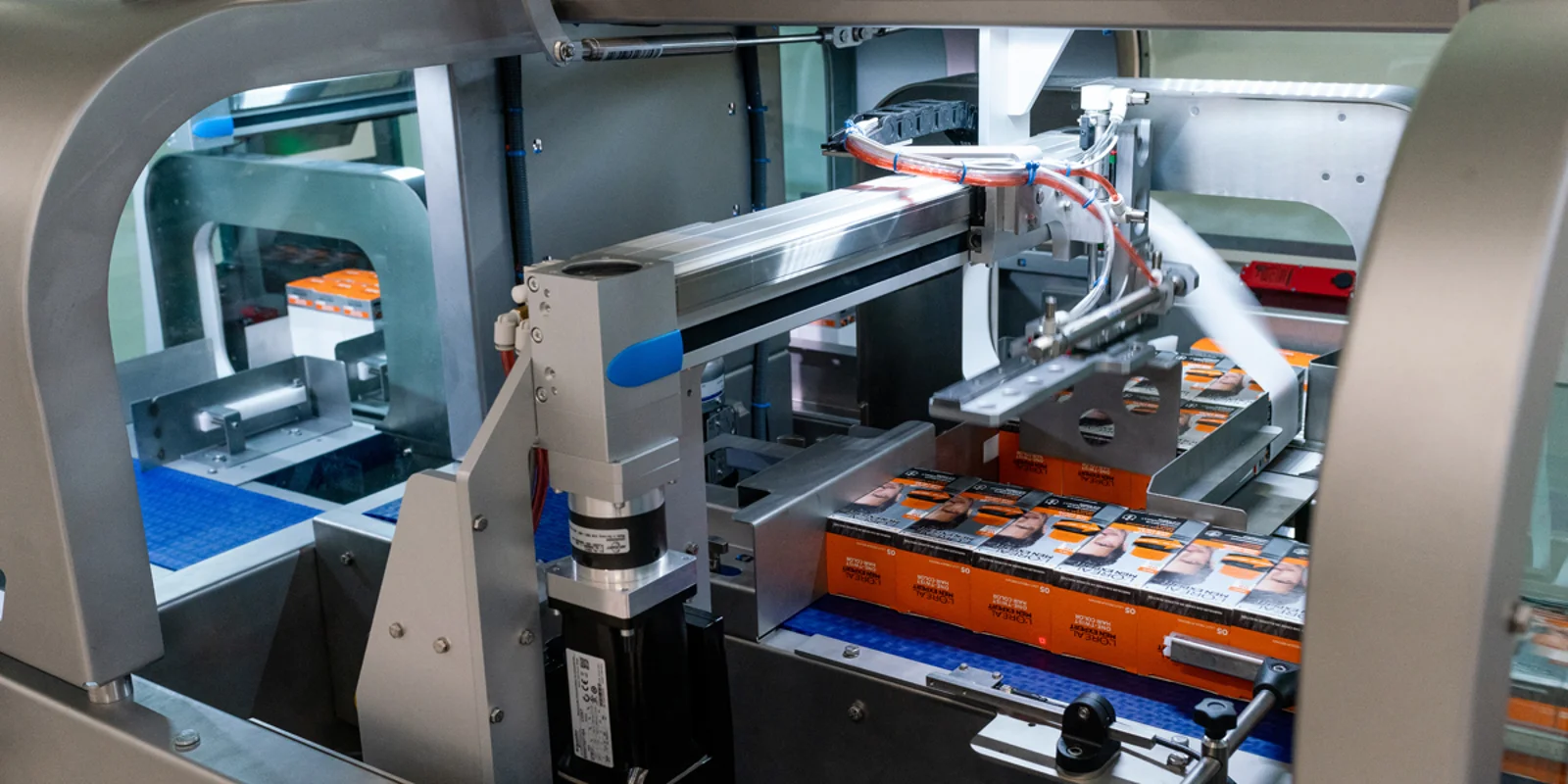

Replacing shrink film with a band

As shrink film (also known as shrink wrap) requires unnecessary use of plastics, it is more often being replaced with a band. Material reductions of 80% or more are no exception.

Banding is more sustainable

By replacing shrink film and reducing the use of plastics and packaging materials, you invest in more sustainable packaging. Depending on your product, you could also pick a paper band. With a Bandall banding machine you don’t just increase the sustainability of your packaging, but also the entire packaging process. A Bandall banding machines uses at least 80% less energy, compared to a shrink film machine.

Reduce packaging material

Because of the advanced band feed system of the Bandall banding machines, you can use the thinnest banding material available (from 35 microns). This doesn’t only help reducing your materials, but also reduces the required storage space. This way, less transport- and storage space is required for your packaging materials.

Advantages of banding

The advantages of replacing shrink film with a band include:

- Reduction in packaging materials and plastics

- Reduction in energy use

- Less transport- and storage space required

- Making your packaging and packaging process more sustainable

Examples

Click on an example for more information

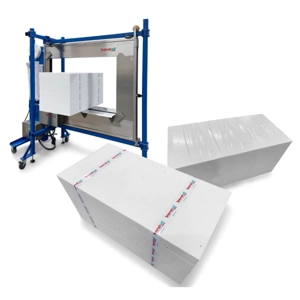

74.7% reduction

75% reduction

Mats & Carpets

92.4% reduction

Laundry industry