The Stand Alone

Place, position, and package with precision

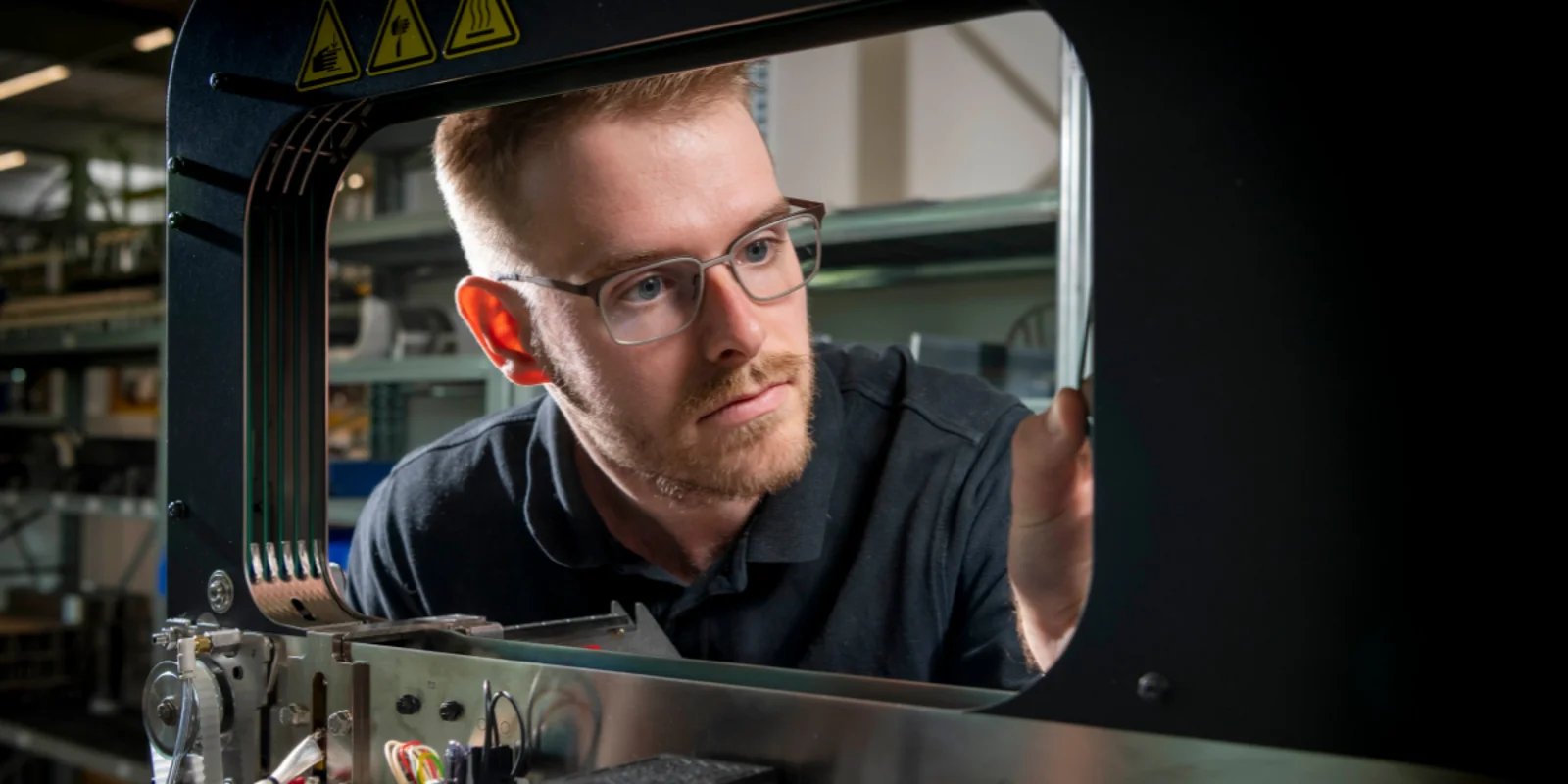

Built for durability, reliability, and simplicity, our Stand Alone machines make sustainable packaging effortless. Designed with one clear goal, to package your products sustainably, they’re ready to handle your product range and deliver consistent results.

Packaging made easier than ever

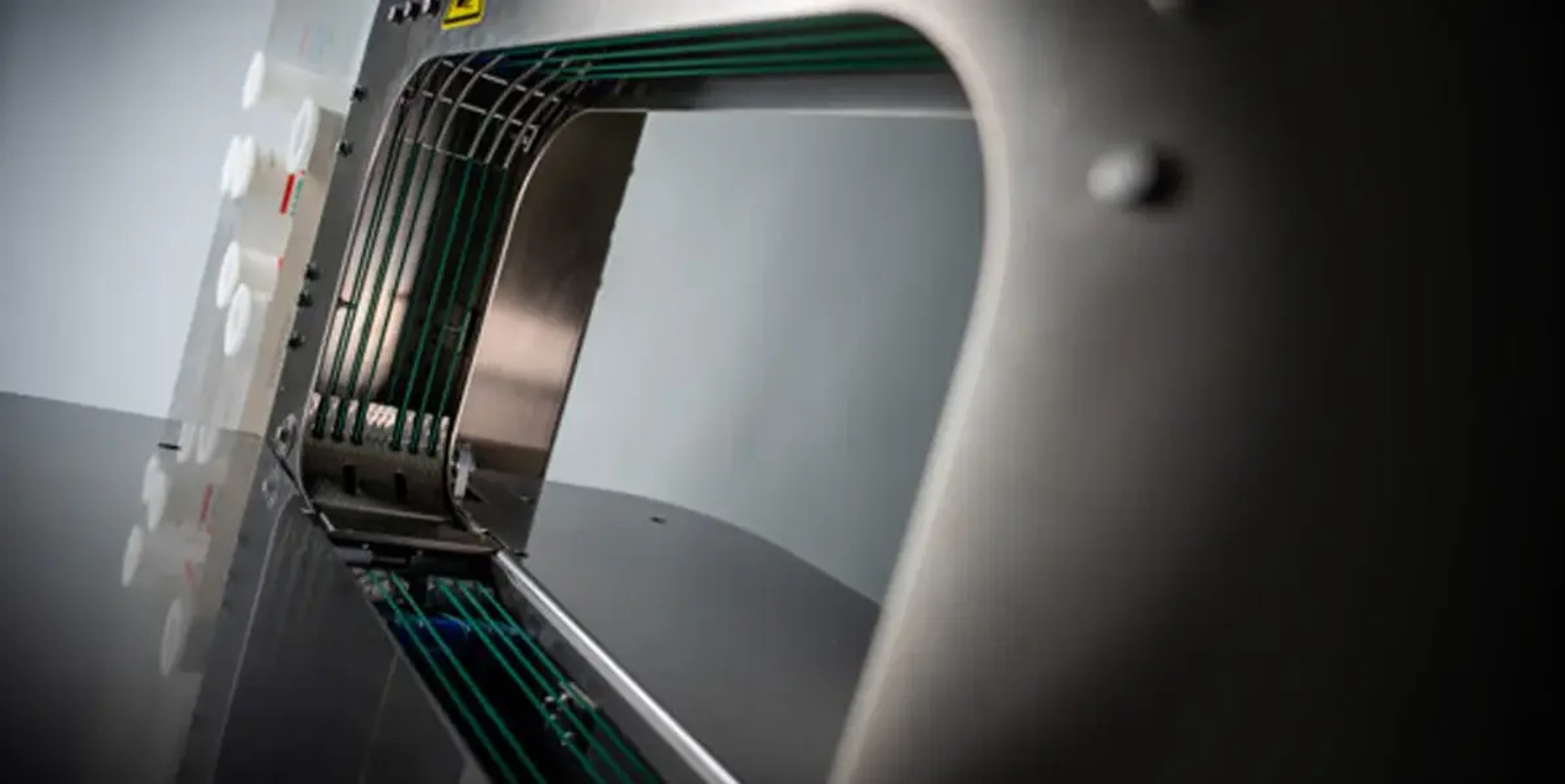

With the Stand Alone, packaging has never been easier. Simply place your product in the machine's arch and let the machine take care of the rest. Simple, reliable, and efficient.

Features of the Stand Alone

The Stand Alone is crafted to simplify and enhance your packaging process, offering a range of smart features that bring you both ease and efficiency:

- Speedy packaging - The fastest machine on the market.

- Automatic operation - Via a sensor or manual via touchscreen or foot switch.

- Adjustable band tension - Ensures precise tension and alignment for every product.

- Compact design - Fits seamlessly into tight workstations.

- User-friendly - Intuitive controls for quick operation.

- Locking wheels - Effortlessly roll your Standalone to wherever it’s needed and lock it securely in place.

- Various arch sizes - Choose from widths ranging from 16 to 136 cm and heights from 15 to 150 cm.

- Unique arch vacuum system - Ensures that the material passes through the arch efficiently and remains firmly in place.

Potential configurations

- Band positioning technology - Optional positioning technology ensures your bands are perfectly placed on every product.

- Multi-width capability - Easily configure your machine to handle various material widths, ideal for a diverse product range.

- Print & Band - Add an integrated printer to include barcodes, product information, or logos directly on the band.

- Bundle press - A press can be incorporated to apply pressure, such as for textiles or cardboard to ensure the products are banded securely.

- External reel holder - Designed for ergonomic roll changes and ideal for those wanting printing capabilities.

- Touchscreen display - Designed for an intuitive user experience using pictograms.

- Stainless steel design - Choose a stainless steel configuration for environments where hygiene and durability are critical.

- Status indicator lights - Add status indicator lights to easily monitor machine operations, including run mode, low material alerts and more.

Band positioning technology

Have specific design wishes for your packaging? Like your logo to appear prominently on the top of your packaging and printed data neatly on the back? Or barcodes to show on the side? Band positioning technology makes this possible, placing each element exactly where it needs to be.

By pairing positioning technology with the Stand Alone and custom-printed bands, you create the perfect foundation for Branding by Banding.

Multi-width capability

Streamline your workflow with the Multi-Width option! Easily switch between different band sizes, making it perfect for your entire product range. Changing the material is quick and hassle-free, allowing you to keep your production moving without any major interruptions.

Print & Band

Need printing capabilities in your operation? With the Stand Alone, you can easily add a printer to your setup! Seamlessly include variable details like barcodes, product information, or logos directly on the band as you package, eliminating the need for a separate labeling step.

Bundle press

Boost the security of your packaging with an integrated bundle press! This feature applies firm pressure to products like textiles, cardboard, or in-mould labels, ensuring they are banded tightly and securely.

Novatrade improved their packaging quality and efficiency

Novatrade, a leading player in window coverings, has made an impressive leap forward in their packaging process. Previously, their products were packaged by hand, a method that was time-consuming, labor-intensive, and led to inconsistent outcomes. All of this changed with the investment in a Stand Alone!

Flexible financing

At Bandall, we understand that investing in a Stand Alone machine is a significant decision, which is why we offer flexible financing options.

- Purchase - Purchase allows you to invest in a sustainable and efficient packaging solution that will enhance your operations for years to come.

- Renting - Renting gives you the flexibility to use the machine for a set period. It includes the possibility of purchasing the machine at the end of the rental term, ideal for evaluating this method of packaging without long-term commitment.

- Trial period - Test the Stand Alone for a week before deciding to purchase or rent.

Service that counts

Bandall offers services such as:

- Training - We provide guidance to help you maximize the machine's efficiency.

- Maintenance - Our engineers can be contacted and asked to come and do checkups for your machine and implement reparations where necessary.

Why band with Bandall?

Download our brochure!

Our range of machines

Stand Alone

Automatic

Modular