How banding makes carpet packaging sustainable

As the packaging industry prioritizes sustainability, businesses are increasingly seeking ways to reduce their environmental footprint. Traditional carpet packaging methods, like plastic wraps and large cardboard boxes, often result in excessive waste and material use. Banding offers a streamlined, eco-friendly alternative by securely holding carpets in place with minimal material. This packaging solution eliminates the need for bulky plastic or cardboard while improving efficiency and sustainability in transportation and display.

Problems with traditional carpet packaging

Traditional carpet packaging often involves the use of large amounts of single use plastics and cardboard. Carpets are typically wrapped, often manually, in thick plastic films or packed in cardboard boxes to keep them rolled up and protected during shipping. This approach results in a significant amount of waste and excessive material usage.

![]()

The benefits of banded carpet packaging

Bands offer a range of benefits, especially when it comes to sustainability, efficiency, and branding:

- Sustainability - By appling a band to your carpet packaging, you significantly reduce material usage compared to traditional packaging methods. By only using a small band to secure the carpet, businesses can cut down on waste, particularly plastic waste, which is a major environmental concern. Banding material is also fully recyclable, free from adhesives, ensuring that the material can easily be recycled.

- Reduced Waste - This sustainable packaging method requires less material, meaning there’s less waste to dispose of at the end of the product’s lifecycle. This helps businesses meet sustainability targets and comply with regulations like the Packaging and Packaging Waste Regulation (PPWR), which aims to reduce plastic use.

- Improved Efficiency - Banding machines offer an automated process that's faster and more efficient than traditional methods. These machines machines can quickly wrap and secure carpets, cutting down on manual labor and reducing human error. This not only speeds up the packaging process but also ensures consistency and accuracy in packaging.

How are bands applied to carpets?

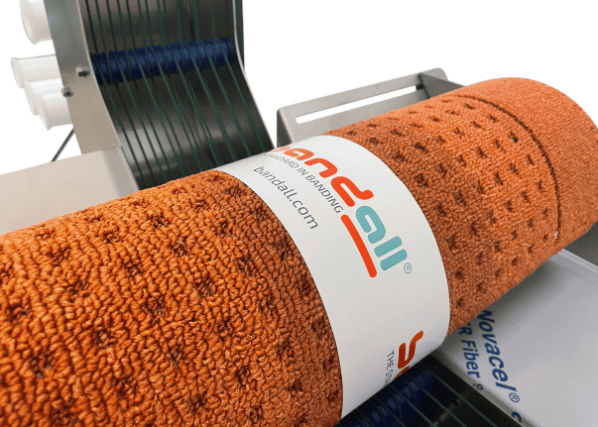

Banding machines apply banding material around carpets in a fast, precise, and fully controlled process. The system is designed to keep carpets tightly rolled during storage or transport, without the need for extra wrapping materials.

- Place the carpet in the banding arch. This can be done manually by an operator or automatically by a conveyor system.

- Once positioned, the machine automatically feeds the banding material around the carpet. The band is pulled to the pre-set tension, ensuring it fits securely around the carpet.

- The banded carpet can then be removed and is ready for storage, shipping, or further processing. The applied band keeps the carpet neatly rolled and stable throughout transport.

Shelf-ready benefits of banded carpet packaging

In addition to its sustainability benefits, bands also offer significant shelf-ready advantages. With minimal packaging, carpets are easier to handle, store, and display. Retailers and distributors can quickly remove the band and display the carpet without dealing with the mess and waste of excessive packaging. This makes carpets more accessible to customers and helps retailers maintain a clean and efficient inventory.

The lightweight nature of the packaging also makes carpets easier to transport, maximizing space utilization in storage and during shipping. By reducing the bulk of traditional packaging, this eco friendly packaging solution allows more products to be transported in a single load.

Branding and printing opportunities

One of the standout features of a band is its ability to incorporate branding and product information directly on the packaging. Carpet manufacturers and retailers can print their logo, product details, and even QR codes or barcodes on the band, providing clear labeling and enhancing brand visibility. This offers a dual purpose—securing the product while also promoting the brand.

A built-in printer can be used to print necessary information directly onto the band during the packaging process, eliminating the need for separate labeling steps. This integrated solution ensures that carpets are not only securely packaged but also ready for display and sale, with all the required product information readily visible.

The future of sustainable carpet packaging

Banding is revolutionizing carpet packaging by offering a more sustainable, efficient, and cost-effective solution. By reducing material usage, minimizing waste, and enabling easy handling, bands improve both the environmental impact and operational efficiency of carpet packaging. Furthermore, the ability to incorporate branding and product information on the band provides an added layer of convenience and visibility.

Applications of banding

Benefits of banding

Banding vs. other solutions

10 Reasons to switch to banding

Zwartz - From shrink wrap to paper bands

Novatrade - Improved quality and efficiency

Packaging food products