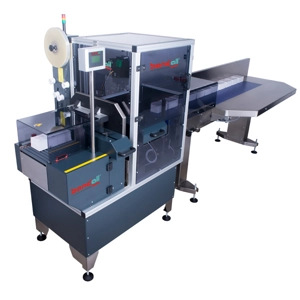

Bandall TRC Series

The TRC machine takes packaging efficiency to the next level with its innovative 'L' shape flow design. Products move seamlessly in a straight line before being smoothly pushed at a 90-degree angle into the arch, creating the signature 'L' shape pathway. Once banded, the products continue effortlessly down the line. Perfect for workspaces with limited space.

Key features of the TRC Series

- Built-in pusher - A robotic pusher ensures the product is correctly positioned in the arch.

- Conveyor belt - The conveyor system seamlessly guides products through the packaging process.

- Status indicator lights - The TRC's indicator lights provide clear alerts, letting you know when it’s running, if an error occurs, or when the material is running low.

- Reel holder - The positioning of the material on the machine makes it easy to replace material quickly.

- Multi-banding - The TRC can apply multiple bands to a product.

- Adjustable height - The adjustable feet make it easy to fit into your existing setup.

Potential configurations

Enhance the power of the TRC with these high-performance add-ons, each designed to boost functionality and provide even greater flexibility:

- Band positioning technology - Add positioning technology and place custom designed bands on your bands exactly as you envision them.

- Printer - Add a printer to include details like barcodes, product information, or logos during the packaging process.

- Programmable servo-control - The infeed pusher automatically adjusts to different product sizes.

- Adjustable component sizes - Tailor the TRC to fit your specific needs with customizable arch sizes and conveyor belt widths.

- Stainless steel design - For environments that require extra durability and hygiene, choose stainless steel.

- Various infeed conveyors - Select from a range of infeed conveyors, including label bander, low-friction food-grade, or roller conveyor options.

Why band with Bandall?

User-friendly design

Maximum uptime

Fastest banding machines

Longest machine life

Smart power management

Designed for easy integration

Easy variable data printing

The thinnest and widest materials

Highly customizable solutions

Worldwide professional support

Klooster succesfully switched to bands

Fish monger Klooster couldn't be more pleased with their decision to switch to from packaging sleeves to bands. Reflecting on the transition, Commercial Director Jac Tijsen expresses his satisfaction: 'Since making the switch, we’ve thrived with a faster, more cost-effective packaging solution.'

Flexible financing

At Bandall, we understand that investing in a machine is a significant decision, which is why we offer flexible financing options.

- Purchase - Purchase allows you to invest in a sustainable and efficient packaging solution that will enhance your operations for years to come.

- Renting - Renting gives you the flexibility to use the machine for a set period. It includes the possibility of purchasing the machine at the end of the rental term, ideal for evaluating this method of packaging without long-term commitment.

- Trial period - Experience the machine in action before making a decision. We offer a one-week trial period, available exclusively in the Netherlands, Belgium, and Luxembourg.

Read more on the TRC by downloading our brochure below!

Our other automatic models

TRL Series

TXL Series