Bandall TRL Series

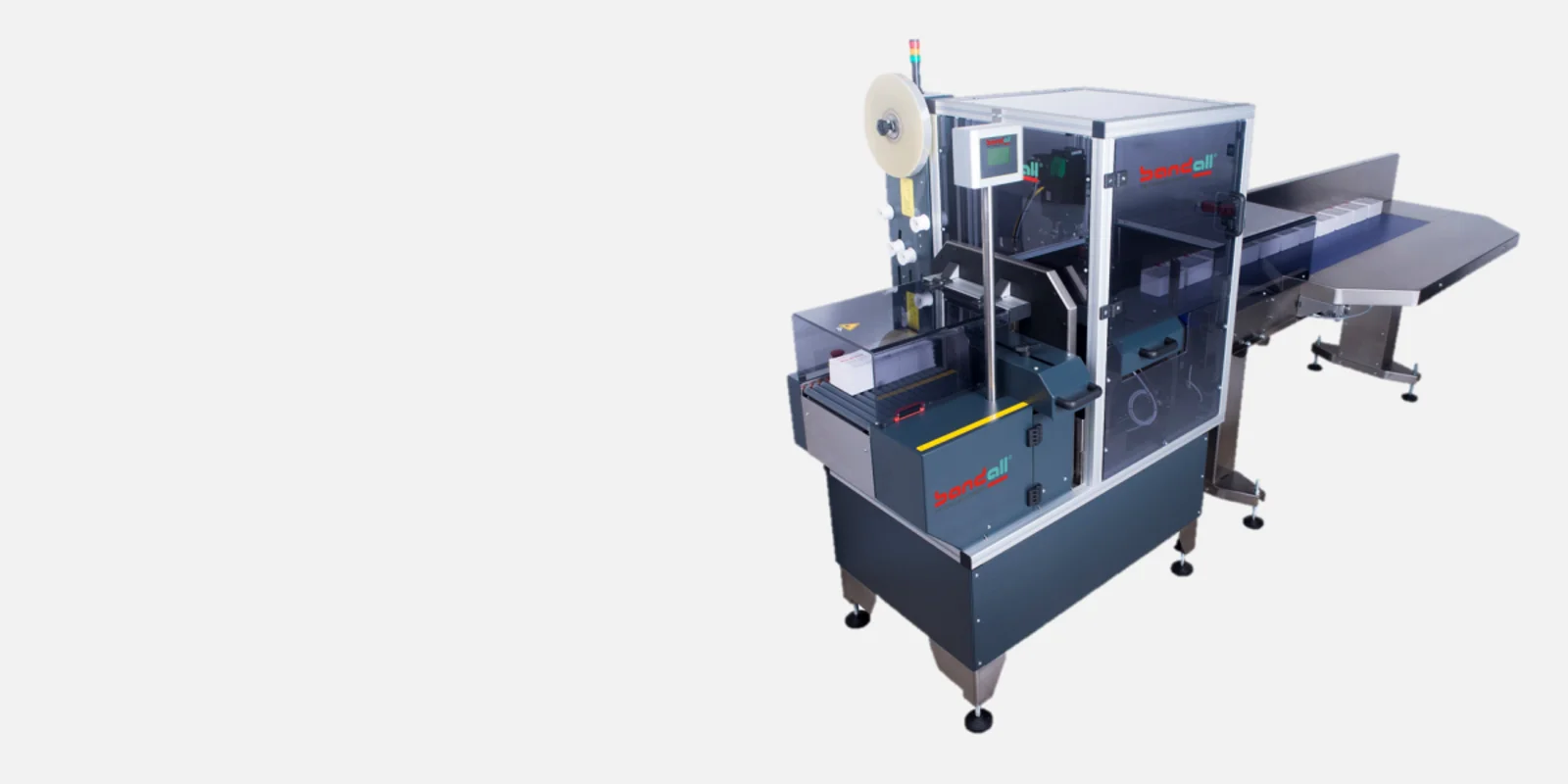

The TRL is built for efficient, automated packaging with a straightforward linear setup. Products are placed on a conveyor belt and moved forward until they reach a dead end. Here the product is gently pushed off the conveyor and into the arch. Once banded the product is then pushed forward onto a parallel conveyor belt, maintaining its linear movement.

Key features of the TRL

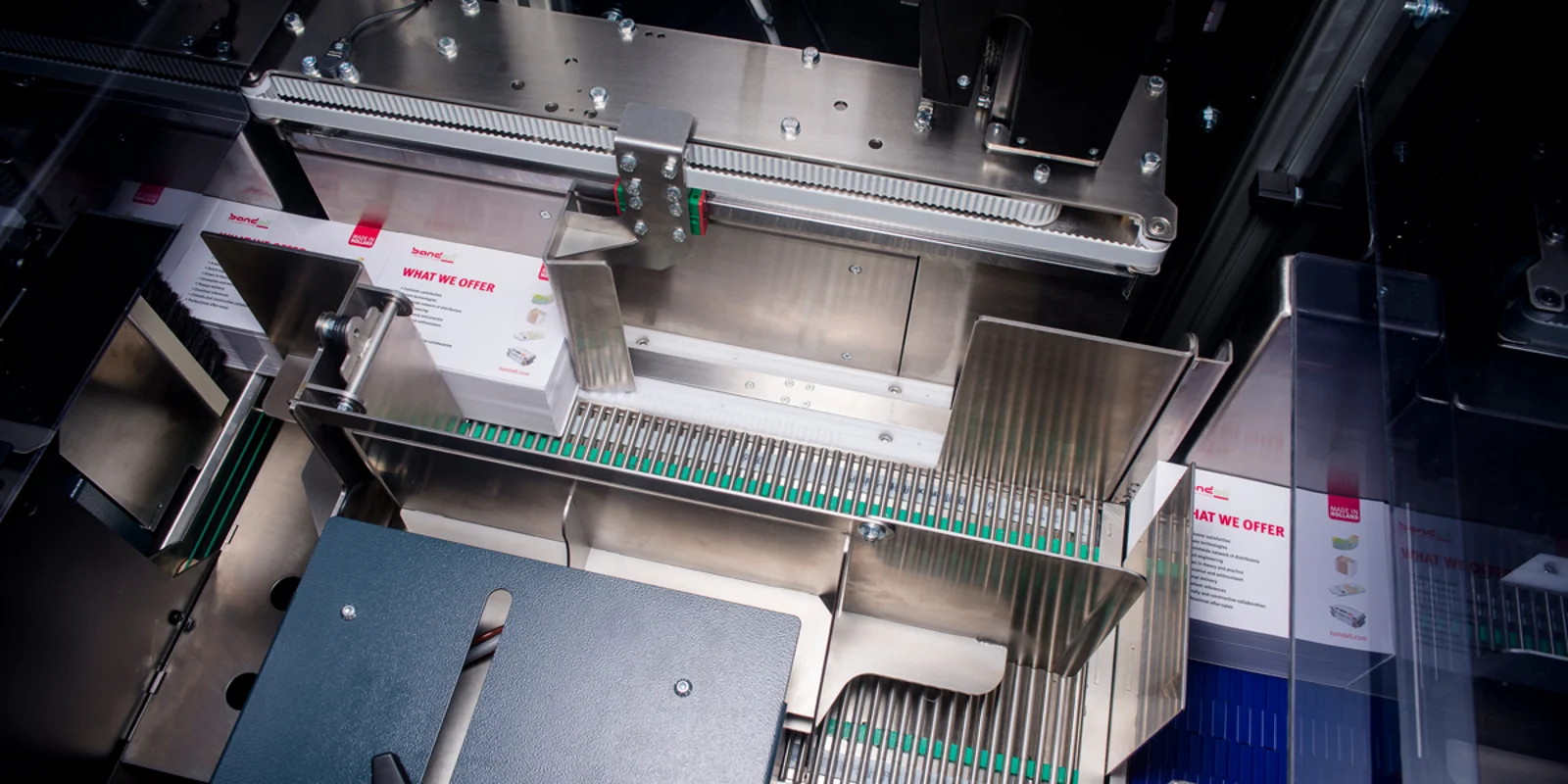

- Built-in pushers - Robotic pushers push and position your product so that they enter the arch correctly.

- Conveyor belts - The conveyor system guides products smoothly through the packaging process.

- Status indicator lights - Intuitive indicator lights keep you informed clearly signaling when it's in run mode or when the material is running low.

- Reel holder - The reel holder makes it simple to replace the packaging material.

- Multi-banding - The TRL can be programmed to apply multiple bands to a product.

- Adjustable height - The adjustable feet make it easy to fit into your existing setup.

- Unique arch vacuum system - Ensures that the material passes through the arch efficiently and remains firmly in place.

Potential configurations

Enhance the power of the TRL with these high-performance configurations, each designed to boost functionality and provide even greater flexibility:

- Band positioning technology - Optional positioning technology ensures your bands are perfectly placed on every product.

- Print & Band - Add a printer to include details like barcodes, product information, or logos directly onto the band.

- Integrated stacking machine - This allows you to efficiently and quickly stack your products before packaging.

- Adjustable component sizes - Tailor the TRL to fit your specific needs with customizable arch sizes and conveyor belt widths.

- Stainless steel design - For environments that require extra durability and hygiene, choose stainless steel.

- Various infeed conveyors - Select from a range of infeed conveyors, including label bander, low-friction food-grade, or roller conveyors.

Why band with Bandall?

Industry expertise

Support and service

Global network of suppliers

Sustainability leadership

Dutch Design

Innovative research & development

Strong global presence

Customer centric

Johannes introduced 100% natural packaging

AGF-Holland has developed a unique and 100% environmentally friendly line of packaging and have called it “Johannes”. This innovative collection features eye-catching punnets and trays crafted from thin natural cardboard, complemented by a fully biodegradable band. Designed for both soft and hard fruits, the Johannes line meets the demands of retailers and supermarket chains seeking uncompromising packaging solutions.

Flexible financing

At Bandall, we understand that investing in a machine is a significant decision, which is why we offer flexible financing options.

- Purchase - Purchase allows you to invest in a sustainable and efficient packaging solution that will enhance your operations for years to come.

- Renting - Renting gives you the flexibility to use the machine for a set period. It includes the possibility of purchasing the machine at the end of the rental term, ideal for evaluating this method of packaging without long-term commitment.

- Trial period - Test the machine for a week before deciding to purchase or rent.

Read more on the TRL by downloading our brochure below!

Our other automatic models

TRC Series

TXL Series