Bundling printed matter

Tired of excess plastic, damaged prints, unstable stacks, and messy bundling slowing you down? Banding is the solution. With a clean, secure, and efficient way to bundle your post-press materials, you can reduce waste, protect your products, and keep stacks perfectly aligned.

Ready to make the switch?

Contact us

Flexible banding machines

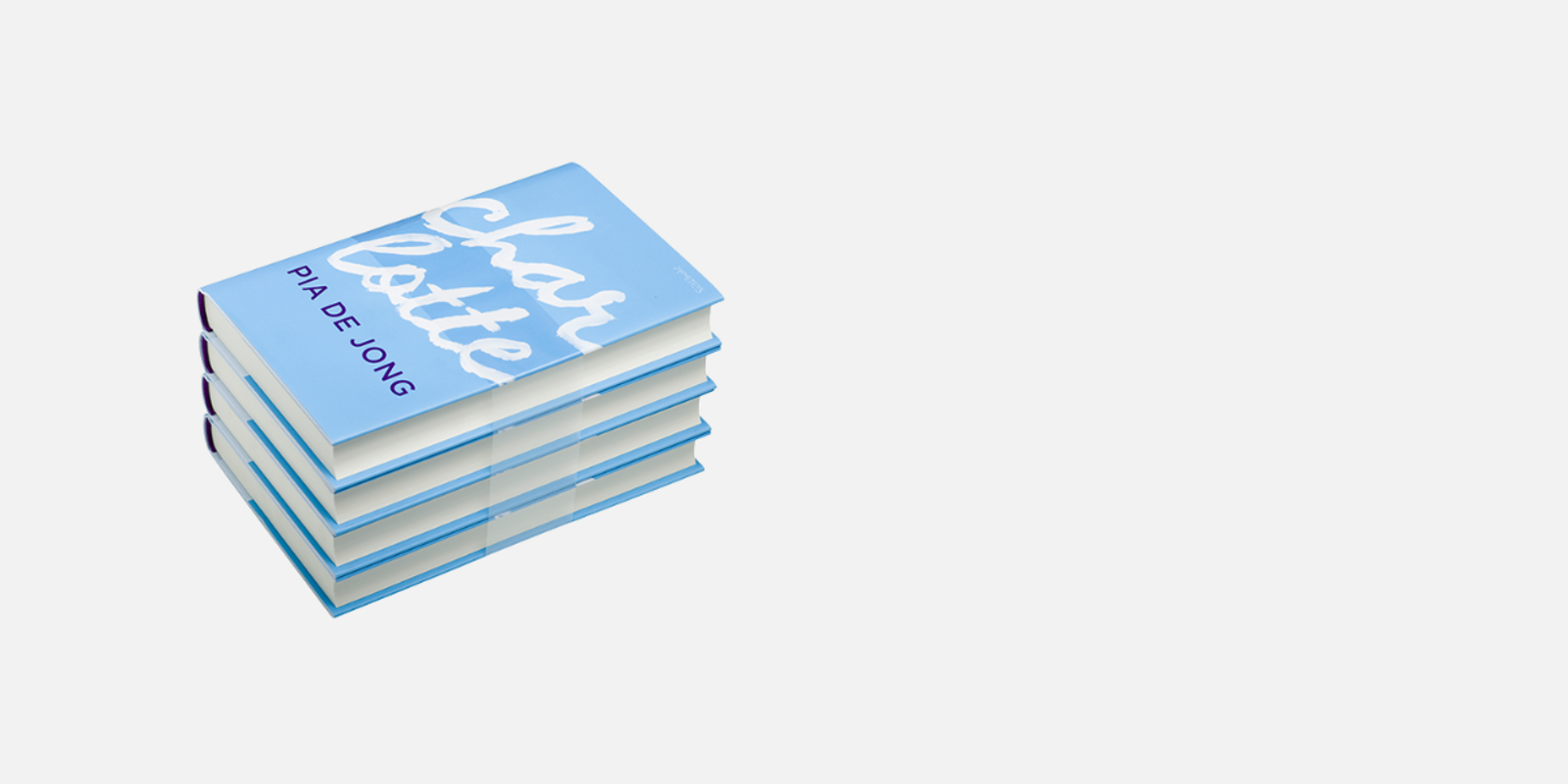

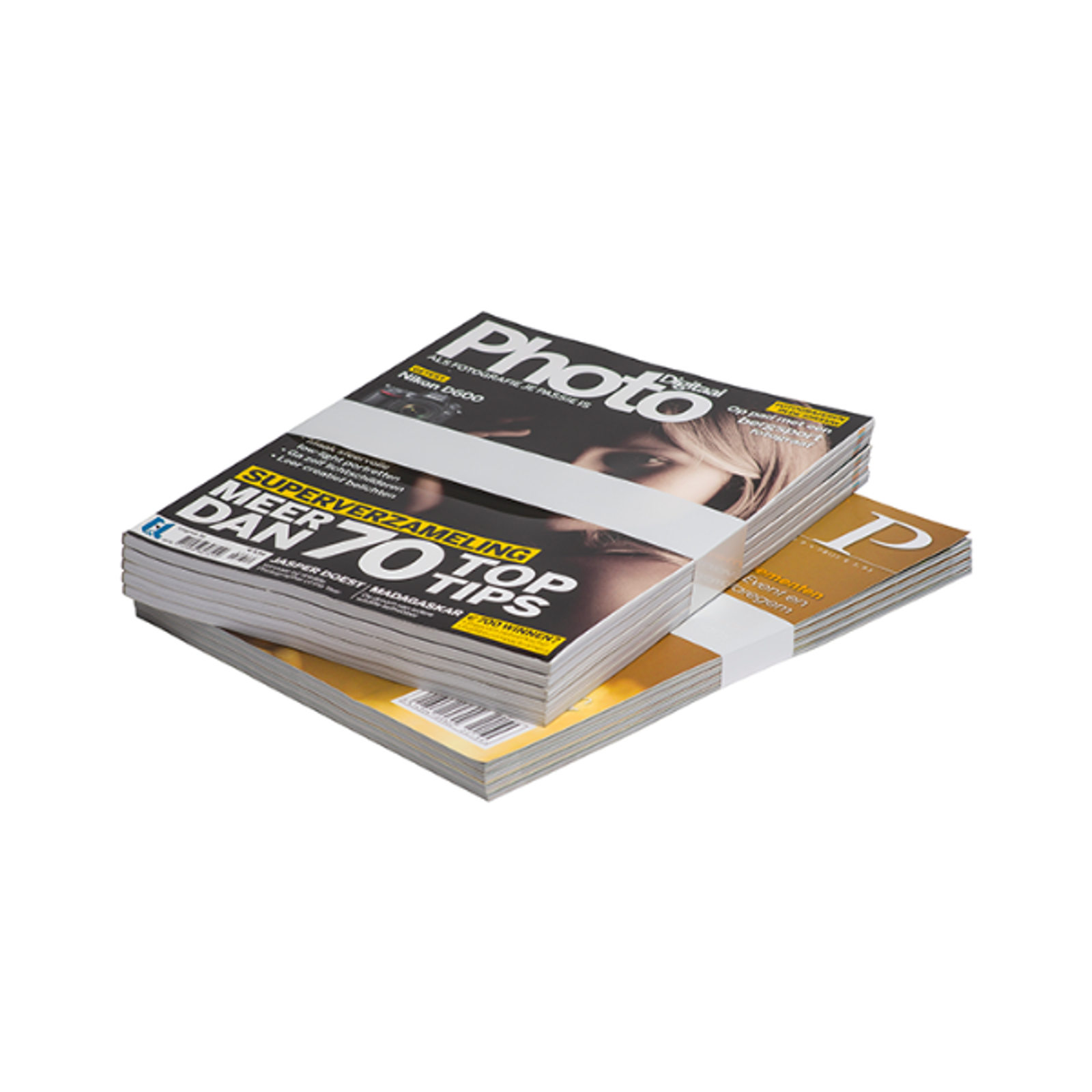

A thin yet durable band can be used to securely bundle your products using minimal material without compromising strength. Unlike traditional packaging methods, banding applies just the right tension, keeping stacks stable while preventing damage to delicate prints.

Benefits of banding

- Reduces waste – Uses minimal material compared to shrink-wrapping or strapping.

- Damage-free bundling – Adjustable tension ensures prints stay secure without crushing edges.

- Neat stacks – Keeps materials perfectly aligned for easy transport and storage.

- Faster and more efficient – Speeds up bundling and packaging, improving workflow.

- Cost-effective – Less material and reduced labor lead to significant cost savings.

- Eco-friendly – Banding material is available in paper and film options, offering a more sustainable alternative.

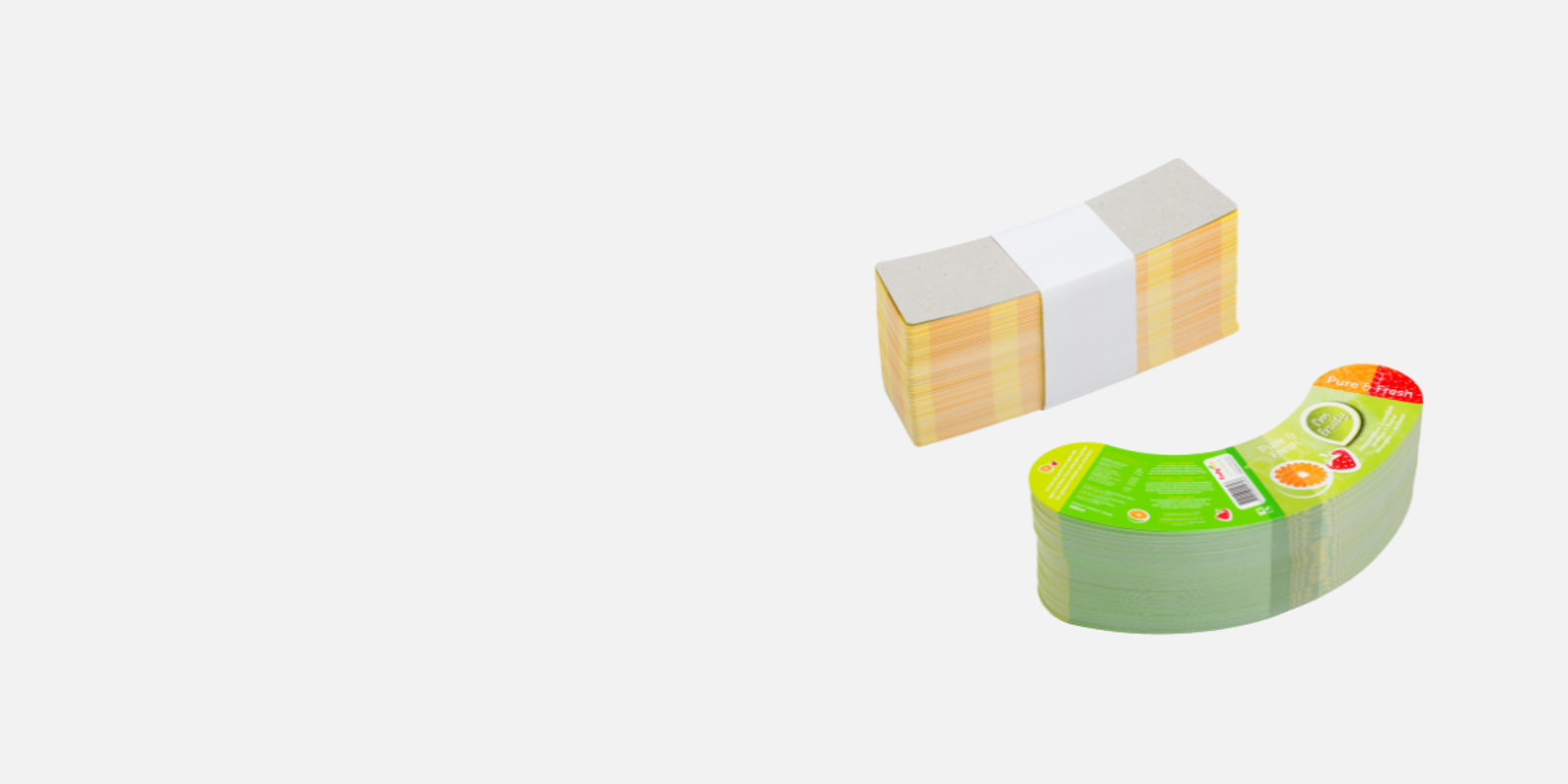

Applications of bands

Branding

Bundling

Labeling

Tamper evident sealing

Seamless automated or manual bundling

Whether automated or manual, stacking your products inside the banding arch is effortless. In an automated setup, your products are precisely placed and stacked, ensuring seamless bundling. For manual operations, products can be easily positioned by hand. With a single, secure band, your post printed products are bundled into a secure stack.

AutomationLess material less hassle

Using minimal material, bands are easy to remove, fully recyclable, and create little waste, reducing environmental impact. Plus, with a single, simple band holding products together, restocking becomes faster and more efficient, keeping your workflow smooth and hassle-free.

Also of interest?

Labels

Valuable papers