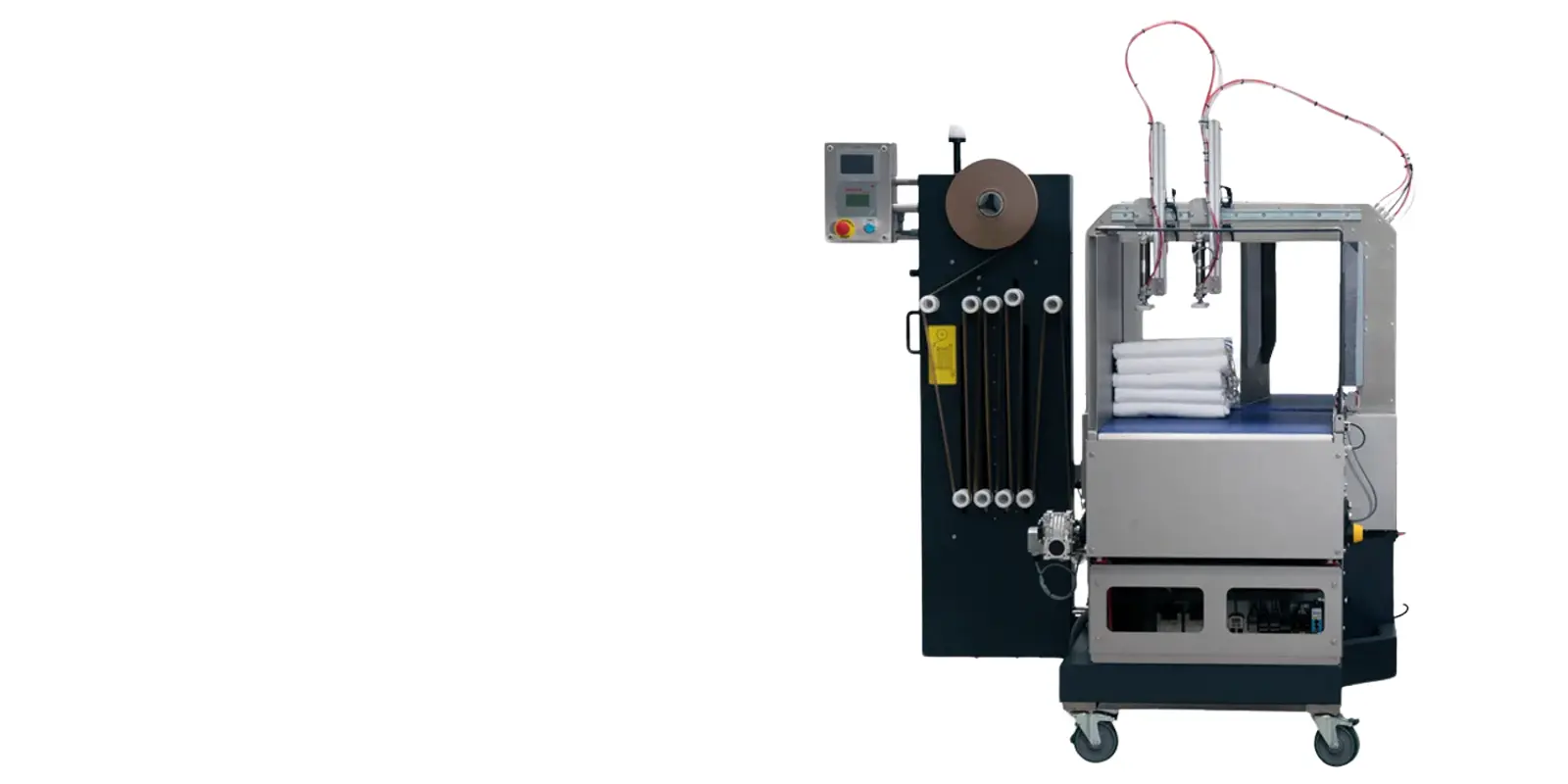

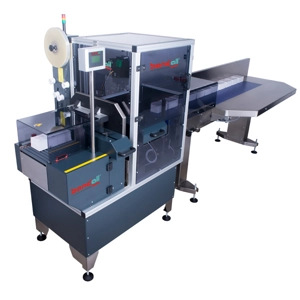

Bandall TRB Series

The Bandall TRB is designed for effortless product movement and takes a unique approach to precision packaging. Unlike our other models, the product is not pushed or guided into the arch. Instead, it moves in a straight line via a conveyor belt into the arch. This machine features an advanced measurement system that accurately detects product length and position and places it perfectly in the arch.

This innovative design gives the TRB a significant edge, effortlessly adapting to various product sizes and lengths with exceptional accuracy and efficiency.

Easily accommodate various product sizes

The smart measurement system allows you to handle various product lengths seamlessly without needing to adjust the machine. Unlike our other automatic machines, the TRB does not have a pusher to move products into the arch.

Key features of the TRB

- Built-in products sensors - These sensors ensure the band is always accurately placed around your product.

- Multi-banding - The TRB is able to apply multiple bands to a product.

- Smart measurement system - This system allows you to handle various product lengths seamlessly without needing to adjust the machine.

- Multi-connector - The multi-connector relays error notifications or material shortage signals to other machines in the production line.

- Smart alerts - Indicator lights inform you on the status of your machine for instance when the machine is running or when the material needs to be refilled.

- Reel holder - The reel holder makes it simple to replace material, minimizing downtime.

- Locking wheels - The TRB can be easily moved around on wheels and locked into position when ready.

Potential configurations

- Band positioning technology - Ensures various elements of the design will always be in the correct place in relation to your product.

- Bundle press - A press can be incorporated to apply pressure, such as for textiles, cardboard, or in-mould labels, to ensure the products are banded more securely.

- Kissing conveyor - A transport belt can be designed to open and close in the arch, allowing flexible products to be efficiently transported through it. Once the product is correctly positioned, the conveyor opens, and the product is banded.

- Side sealing - Side sealing can be utilized if it is better suited for packaging a specific product or accommodating a particular setup. This method is often paired with a kissing conveyor.

- Printer - Add a printer to include variable details like barcodes, product information, or logos directly onto the band.

- Stainless steel - For environments that require extra durability and hygiene, choose stainless steel.

Why band with Bandall?

User-friendly design

Maximum uptime

Fastest banding machines

Longest machine life

Smart power management

Designed for easy integration

Easy variable data printing

The thinnest and widest materials

Highly customizable solutions

Worldwide professional support

Zwartz yielded impressive results by switching to bands

The switch to dark brown paper bands has yielded impressive results for Zwartz. This new packaging solution has not only provided a refined and natural look but also led to a significant increase in sales figures. Customer satisfaction has clearly risen, which is reflected in the positive sales results. In short, Zwartz can confidently say that this change has been a successful and valuable investment.

Flexible financing

At Bandall, we understand that investing in a machine is a significant decision, which is why we offer flexible financing options.

- Purchase - Purchase allows you to invest in a sustainable and efficient packaging solution that will enhance your operations for years to come.

- Renting - Renting gives you the flexibility to use the machine for a set period. It includes the possibility of purchasing the machine at the end of the rental term, ideal for evaluating this method of packaging without long-term commitment.

- Trial period - Experience the machine in action before making a decision. We offer a one-week trial period, available exclusively in the Netherlands, Belgium, and Luxembourg.

Read more on the TRB by downloading our brochure below!

Our other automatic models

TRL Series

TRC Series