Royal Sens saves by smart bundling

Royal Sens originated at the end of the 19th century as a family business and lithographic printing company. Since 1979, the company has been fully dedicated to the production of labels. Where bundles of labels were once manually wrapped in brown paper, this method became inefficient as the company grew. The switch to banding proved to be the ideal solution, and since then, Royal Sens has been a loyal user of Bandall systems for decades.

Royal Sens, a trusted name in the packaging industry

Royal Sens has grown internationally into a trusted name in the packaging industry. With four locations in three countries and around 230 employees, they produce nearly 9 billion wet-glue labels and flexible packaging products annually. In addition to the food and beverage industry, Royal Sens also supplies manufacturers of household and pharmaceutical products. Virtually all leading European producers of A-brands are loyal customers of the Rotterdam-based family company.![]()

![]()

The time before automation: manually packing labels

In the past, employees would wrap each bundle of labels in brown paper, a process that required a lot of time, energy, and manpower. While this method worked well for the relatively small production volumes back then, it also had significant drawbacks. It was not only labor- and cost-intensive, but also physically demanding. In addition, there was little flexibility, and scaling up efficiently proved difficult, as the process relied entirely on manual labor.

A sustainable and future-proof solution

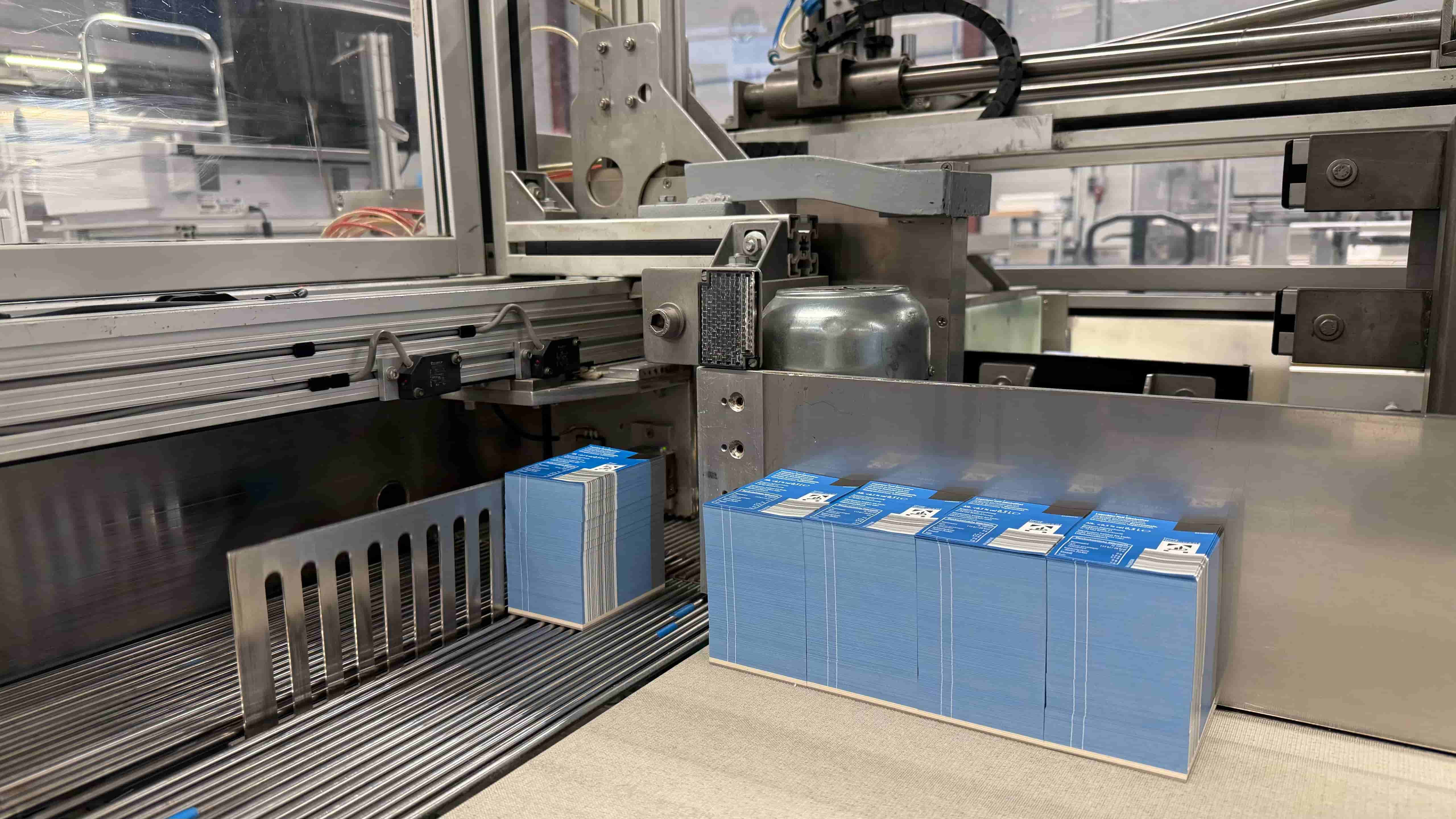

As Royal Sens continued to grow, so did its production volumes. The need for a scalable and more efficient bundling solution became increasingly clear. At the same time, the company wanted to produce and package more sustainably and with a focus on the future. This led to the development of a new packaging line, which incorporated a Bandall banding machine. The machine bundles the labels directly after printing and cutting. The labels are automatically grouped on a conveyor belt, typically into bundles of 1,000. However, depending on the paper thickness, they may also be bundled in sets of 750 or 1,250.

"The machines are easy to operate, and Bandall is a reliable partner for maintenance and service. It’s been a great collaboration.".

— Production manager Abdel

The desire to work not only more efficiently but also more sustainably has been fulfilled with the introduction of banding. Bands use significantly less material. Customers also appreciate the paper bands from a practical perspective: they are easy to remove, easy to recycle, and generate significantly less packaging waste.

Growing with an eye on the future

Royal Sens is looking ahead. Production capacity continues to grow, and in the coming years, further automation is planned, including the use of robotic arms and automatic stackers. Abdel: "As we continue to scale up, we will definitely choose Bandall’s automatic banding machines again. We highly recommend Bandall."Do you also want to bundle sustainably and efficiently?

Let's explore the banding opportunities together.

Applications of banding

Benefits of banding

Banding vs. other solutions

10 Reasons to switch to banding

Zwartz - From shrink wrap to paper bands

Novatrade - Improved quality and efficiency

Packaging food products