What is banded packaging?

Smart, sustainable, and efficient

How banded packaging works

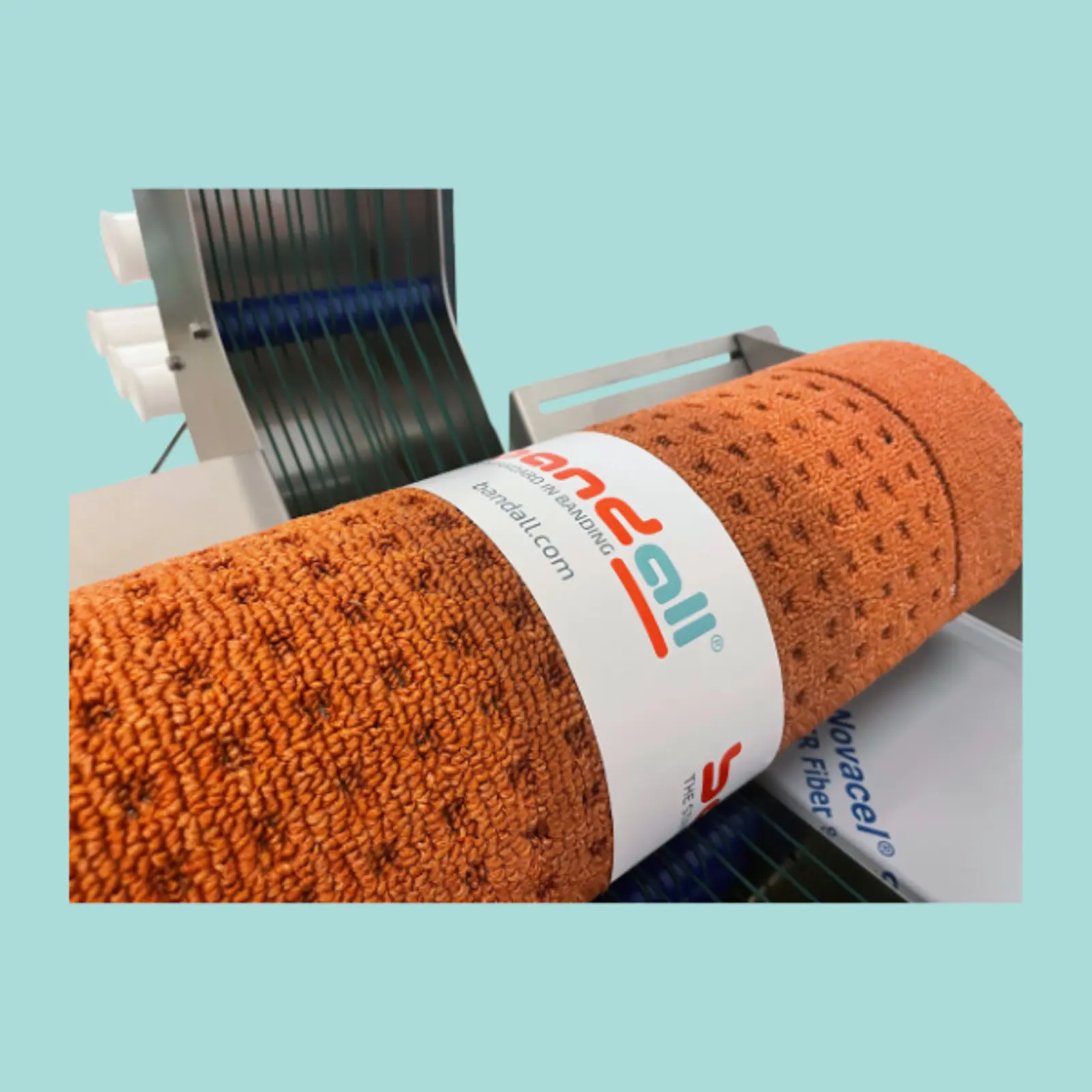

Banded packaging is produced using specialized banding machines that wraps and seals band material around product(s) quickly and consistently.

The process typically follows three steps:

- Product placement - Products are positioned in the banding machine manually or automatically.

- Band application - Paper or film banding material is wrapped around the product and sealed at the ideal tension.

- Finished packaging - The finished package is released, ready for handling, display, or transport.

This reliable process creates neatly packed products without bulky or wasteful packaging.

Why choose banded packaging

Better Sustainability - Using a single narrow band reduces material use dramatically, helping brands meet sustainability goals and reduce waste.

Reduced Packaging Costs - Less material and simpler machine processes mean lower packaging costs, reduced energy use, and faster throughput on the production line.

Strong Branding Opportunities - Banded packaging can be printed with logos, colors, or messaging that reinforces your brand identity in a clean and premium way.

Compact and Efficient Packaging - Bands keep products secure without adding bulk, improving storage efficiency, and reducing transport cost.

Our banding machines

Stand Alone

Automatic

Modular

Tailor-made

Banded packaging vs traditional solutions

Banded packaging vs shrink wrap: Bands use far less material and energy, resulting in lighter packaging with less waste.

Banded packaging vs sleeves: Banded packaging uses a minimal band to brand products without covering the product.

Banded packaging vs adhesive labels: Banded packaging requires no adhesives and offers a more versatile branding and sealing solution.

Banding material

When it comes to banded packaging, the material you choose can make all the difference in both functionality and customer experience. We offer two material options:

The need for smarter, sustainable packaging

New regulations such as the European PPWR are pushing companies to reduce packaging waste, improve recyclability, and use fewer materials. Traditional packaging methods are no longer sufficient to meet these requirements.

How banded packaging supports modern packaging regulations:

- Significantly reduces packaging material usage

- Supports a circular economy through mono material packaging

- Enables easy recycling without separating components

- Uses material made from sustainable paper or recyclable film

Start using banded packaging today

Whether you’re bundling products for display, improving sustainability, or enhancing your brand presence, banded packaging offers a smart packaging solution with measurable benefits.

Get started with our effective banded packaging solution that fits your production needs and packaging goals.