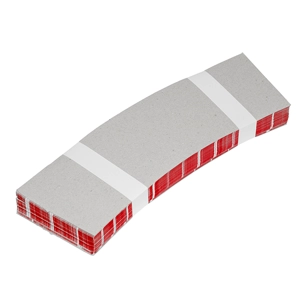

Bundling labels by banding

Bandall bundling machines guarantee neat and tight bundles of any type and shape of labels. Thanks to the advanced vacuum band feed-through system of the machines, this takes place quickly, flexibly and without damage to the bottom and top labels. We offer Stand Alone machines and state-of-the-art fully automated banding lines that can be extended with, for example, a label line and a press.

The unique Bandall vacuum feed system eliminates friction in the arch. This helps to create a faster and more reliable band transport. The advantages include:

- Fewer parts that are subject to wear

- Only banding system compatible with very large arch sizes

- Side sealing and top sealing possible without affecting quality or performance

Ensured of neat and tight bundles

For over 30 years, in-mould label and label printers have been putting their trust in Bandall machines for the damage-free bundling of all types of (plano) labels. Stand Alone or integrated in a fully automated line, the Bandall machine is guaranteed to bundle perfectly, without damage, and ensures neat and tight bundles of labels. Including labels in different sizes or special shapes:

- Straight labels

- Die-cut labels

- In-mould labels

- Very narrow labels

- Very small labels

- Tax labels

With an optional measuring system, you are able to bundle a mix of different label sizes.

Bundling in-mould labels as a specialist activity

Bundling In-Mould labels (IML) is a speciality in itself. This is due to the often wafer-thin labels, combined with irregular shapes. Bandall has developed different fully automated bundling systems that focus entirely on this. This video, for example, shows how a special Bandall TRBS bundling machine uses a so-called kissing conveyor. It allows the bundling of stacks of IMLs, without using cardboard plates on the bottom and top side of the stacks.

With the so-called Kissing Conveyor option, the two-driven conveyor belts are brought towards each other in the banding arch shortly before banding. The benefit of this is that products, such as short labels or bundles of laundry, cannot fall between the conveyor belts. This way, the products are consistently placed accurately in the banding arch.

Labels banded by our machines:

Start bundling labels by banding!