Stand Alone banding machines

Our Stand Alone machine has a modular structure and is known for its flexible, durable, and highly reliable performance. An almost endless number of options such as stainless steel, Multi-Width, printer, positioning system, or press make the Stand Alone extremely versatile. With a constant focus on innovation and support, the machine meets the wishes of clients and the industry.

Tailored to your wishes

The Bandall Stand Alone consists of standardized modular components. As a result, the Stand Alone machine can be delivered quickly and easily, completely tailored to your wishes. It's standard available in various arch sizes and is suitable for 28, 40, 48, 60, 75, 100 and 125 mm wide banding material, paper or film. Different widths are also possible upon request. With the Multi-Width option, you can achieve even more flexibility, as it allows you to run multiple band widths on the same machine.

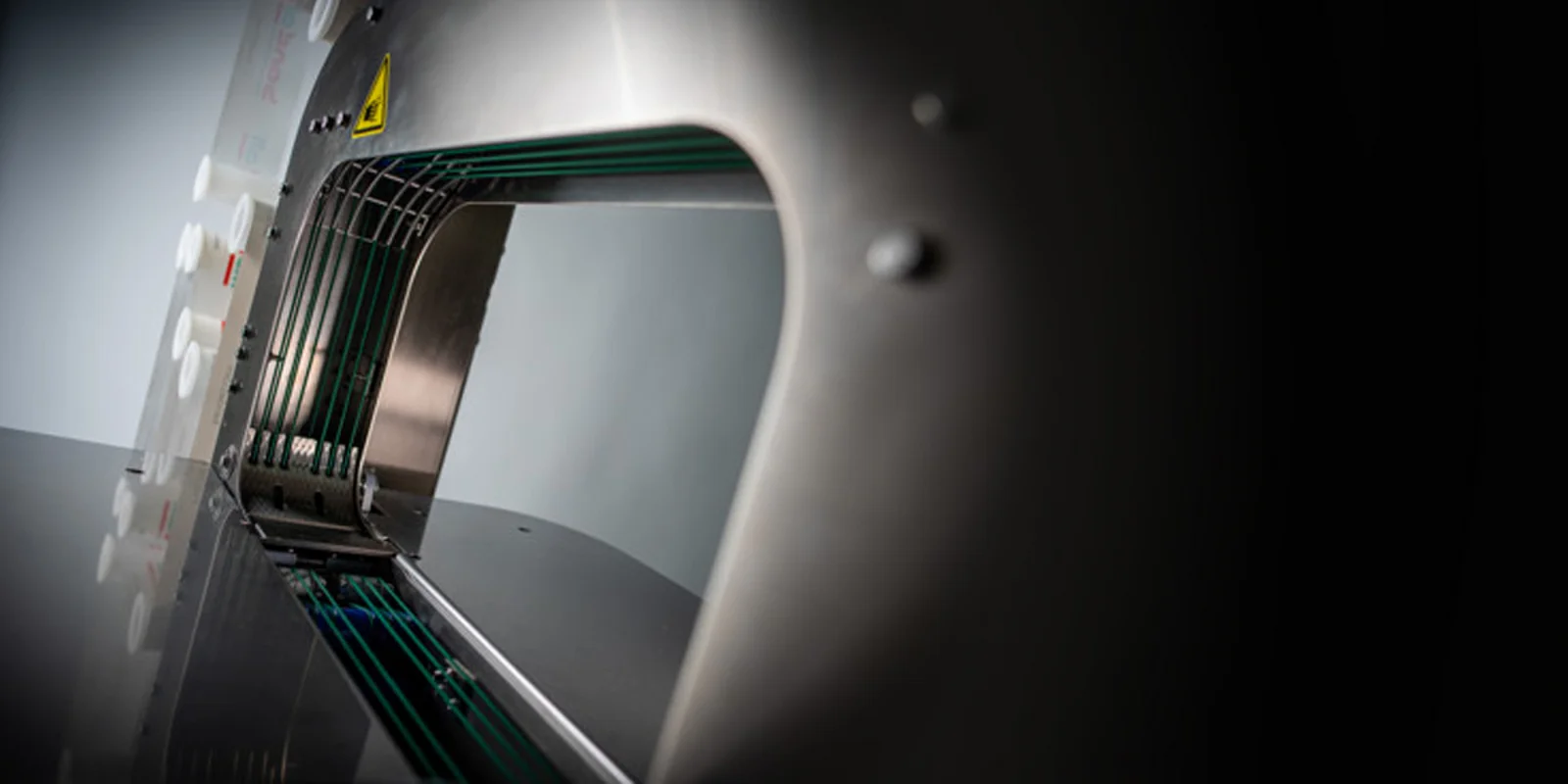

Unique band feed-through system

The way in which our machines guide the band to the machine arch is unique on the market. Thanks to the vacuum feed-through system and the Ultra Clean Seal system (UCS), you can be assured of a smooth, fast, and clean packaging process. Friction in the arch is completely eliminated.

- Fewer wear parts

- compatible with very large arch sizes

- Side sealing and top sealing possible without affecting quality or performance

- Process materials starting from 35 mµ

Branding by Banding model

The stainless steel Branding by Banding model combines advanced positioning technology with optional printing capabilities to deliver unparalleled flexibility in labeling and bundling. Crafted for excellence, this machine enhances your product's shelf appeal with precisely positioned bands, making it the most versatile solution on the market.

Adjustable to various band widths

The Multi-Width option allows you to adjust the machine to a number of other band widths in no time. Simply add or remove components, like the channel reducer, to or from the arch, change the material, and you are ready to go! A machine running 100 mm material, can now be adjusted to, for example, 90 mm or 75 mm by using these reducers. Or a machine using a width of 75 mm can then be adjusted to 60 mm or 48 mm. This way the already flexible Bandall machine is even more flexible.

Success stories from our customers:

Zwartz | Move to paper packaging and growth

Fish monger Klooster | From sleeve to band

Novatrade | Improved quality and efficiency

Johannes | 100% Pure Natural Packaging

Rent a Bandall

Test our machines without investing

- No investment required

- Ideal for testing a new packaging concept

- Flexible for seasonal work

- Switching from renting to buying is simple

Why band with Bandall?

- Damage-free packaging process

- Unique band feed-through system

- Lowest cost of ownership

- User-friendly operation

- Significant reduction of packaging material

- Clean and odour free, thanks to the Ultra Clean Seal (UCS)

- Longest machine life

- Worldwide professional support and service

- Global network of packaging and material suppliers

- PPWR ready

Other Bandall Machines:

Tailor-made banding machines

Multi-head banding machines

Fully automatic banding machines

Download our brochure!