Quality products, inefficient packaging

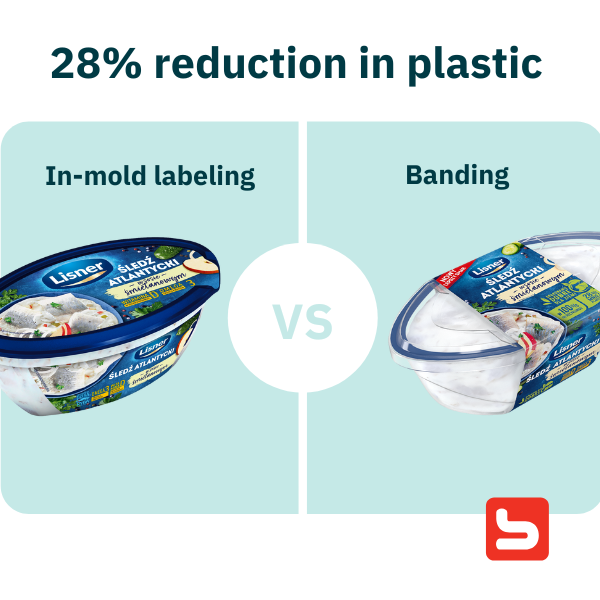

Lisner, a leading name in herring preparations, salads, and sandwich spreads in Poland, is known for its dedication to quality and efficiency. Delivering fresh products across Europe requires not just great recipes but also efficient packaging. For years, Lisner used in-mold labeling (IML) on polypropylene tubs for branding and labeling, however, this method had a major drawback. Their packaging was heavier than what they would have wanted, resulting in high expenses.

Lisner chooses banding

Lisner knew a better option was out there. As they started their journey looking for a better alternative, they recalled seeing and hearing about banding at trade fairs. Intrigued by its potential, they turned to Voltapak, Bandall’s distributor in Poland, to see if banding could solve their problem.

To see banding in action, Lisner invited Bandall for an on-site demonstration. They tested how bands would look on various products, with a particular focus on their herring products. The results were impressive. Banding proved to be a perfect match for Lisner’s transparent tubs.

The sleek band covered only a small portion of the packaging, allowing for greater visibility of the product inside. At the same time, it offered a unique space for branding, enhancing the product’s appearance. The thin film band added little to no extra weight, creating a secure seal while fully supporting Lisner’s goal of using lighter, more sustainable packaging materials. Additionally, because no adhesives were used, the band could be easily removed and recycled.

The choice was clear: Lisner decided to replace in-mold labels with sleek film banding material and began integrating Bandall’s automated banding machines into their operations. However, while selecting the solution was easy, implementing it came with challenges...

Overcoming challenges

Meeting high-speed packaging demands

The first major challenge was achieving the required packaging speed. Given Lisner’s large-scale operations, they needed machines capable of packaging 120 herring products per minute. However, a single automated banding machine typically handles only 20-30 products per minute. This was far below the required output.

To bridge this gap, Bandall’s engineers developed a custom solution. Instead of using individual machines, they custom designed automated TRC banding machines with multiple banding heads. This innovation allowed multiple products to be banded simultaneously, ensuring that Lisner’s production speed target was met.

However, while this solution addressed the speed challenge, it introduced a second challenge: space constraints.

Integrating larger machines in a limited space

The implementation of multiple TRC banding machines required significantly more floor space than the previous setup. To accommodate them, Lisner had to expand their production site and carefully plan for the necessary adjustments. This process took time and added complexity to the transition.

Once the machines were installed and operations began, Lisner faced an unexpected third challenge: machine malfunctions.

Preventing machine malfunctions

Shortly after Lisner launched their banding process, an unexpected issue brought production to a halt. Their machines had stopped working. The cause? Oils and grease from the herring products were accumulating inside the machines. This was a unique challenge Bandall had never encountered before.

But rather than stepping back, Bandall stepped up. Determined to help Lisner succeed, Bandall quickly identified the problem and provided a practical solution. To minimize downtime and keep operations running smoothly, regular cleaning was introduced as a key part of the process.

To support Lisner’s team, Bandall’s engineers delivered on-site workshops showing exactly how to disassemble, clean, and reassemble the equipment with confidence and efficiency.

With these maintenance protocols in place, Lisner was able to maintain high productivity while preventing further disruptions.

Bandall’s automated banding machines

Despite the initial hurdles, investing in banding proved to be a smart decision, offering a range of benefits that far outweighed the challenges. This new solution brought several key advantages:

Lower costs

-

Substantial savings from reduced packaging weight

- Even with added maintenance staff and facility upgrades, overall costs went down

Enhanced sustainability & circular packaging

- Mono-material (plastic tray + film band) packaging reached 98% recyclability (Cyclos certified)

- Non-adhesive bands are easy to remove → simplified recycling

- 28% plastic reduction, saving 400 tonnes/year

Improved consumer appeal

- Transparent packaging enhances product visibility

- Sleek bands allow branding with minimal coverage

Increased sales

- The packaging upgrade resulted in a 9% sales increase

Enhanced product security

- Bands act as tamper-evident seals

- Improved product integrity and strengthened consumer trust

Lighter packaging, cost savings, and a future proof solution achieved

Lisner’s transition to banding marked a significant step toward a more cost-effective and sustainable future. By adopting this innovative solution and overcoming implementation challenges, they have enhanced product appeal, reduced their environmental footprint, and saved substantial amounts of material and costs.

With 66 million herring products successfully banded and considerable reductions in material usage, Lisner has proven that large-scale packaging can be both practical and environmentally responsible. Their success serves as an inspiring example for the food industry, demonstrating that sustainability and efficiency can go hand in hand and encouraging other companies to explore greener packaging solutions.

Curious to see if banding can help you save material?

Looking to give your packaging a sustainable edge or have samples created? No problem! Our specialists are ready to discuss the possibilities with you, free of charge.

Applications of banding

Benefits of banding

Banding vs. other solutions

10 Reasons to switch to banding

Zwartz - From shrink wrap to paper bands

Novatrade - Improved quality and efficiency

Packaging food products